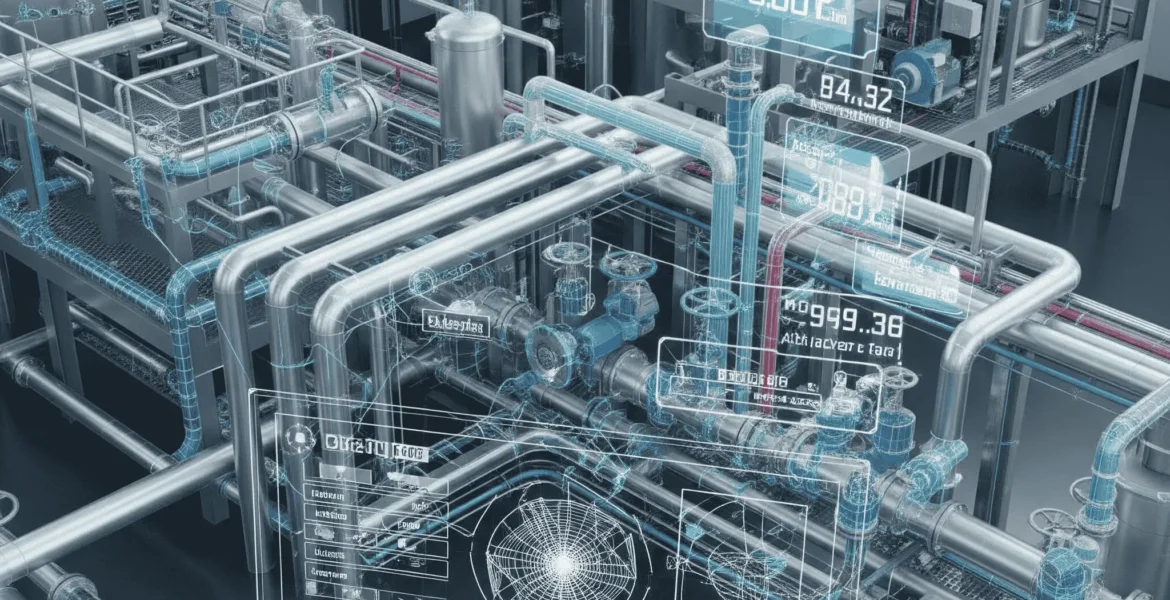

3D Modeling in Piping Design: Revolutionizing Plant Layout and Visualization 🌐

0 comments

3D Modeling in Piping Design: Revolutionizing Plant Layout and Visualization 🌐

Introduction:

- The shift from 2D drafting to intelligent 3D modeling in plant design. The transformative impact of this technology.

Evolution of Piping Design: From 2D to 3D:

- Limitations of 2D: Difficulty in visualization, prone to clashes, manual MTOs, challenges in managing changes.

- Emergence of 3D CAD and dedicated plant design software.

Key Advantages of 3D Modeling in Piping Design:

- Enhanced Visualization: Realistic representation of the plant, easier to understand complex piping runs and equipment layouts.

- Clash Detection: Automatic identification of interferences between piping, structure, equipment, cable trays, HVAC, saving costly rework during construction.

- Improved Accuracy and Consistency: Centralized database ensures all deliverables are based on the same model. Reduced human error.

Automated Deliverable Generation:

- Piping isometrics and spool drawings.

- General Arrangement (GA) drawings.

- Bills of Materials (BOMs) / Material Take-Offs (MTOs).

- Support drawings.

Streamlined Interdisciplinary Collaboration:

- All disciplines work on a common model, improving communication and coordination (e.g., structural steel, equipment, civil).

Facilitates Design Reviews:

- Interactive model reviews (e.g., using Navisworks, SmartPlant Review) with clients and internal teams.

Integration with Other Engineering Activities:

- Pipe stress analysis software (export/import capabilities).

- Procurement systems (MTO data).

- Construction planning and simulation.

Lifecycle Data Management:

- The 3D model can become a “digital twin” for operations and maintenance.

Popular 3D Piping Design Software Suites:

- AVEVA Solutions (PDMS, E3D).

- Hexagon PPM / Intergraph (SmartPlant 3D, PDS).

- Autodesk (AutoCAD Plant 3D).

- Bentley Systems (OpenPlant Modeler).

- CADWorx.

- Key features: Specification-driven design, component libraries, clash management, drawing production.

The Role of Specifications in 3D Modeling:

- How piping specs (defining allowed materials, components, dimensions based on ASME B31.3 and other codes) are built into the software to ensure compliant design.

Challenges and Considerations:

- Initial software cost, training requirements, managing large models and databases.

Conclusion & Call to Action:

- 3D modeling is no longer a luxury but a standard in modern piping design. Proficiency in these tools is essential for competitiveness and efficiency. Hands-on training courses for specific 3D plant design software (like S3D, PDMS/E3D, or Plant 3D) are crucial for designers and engineers to master these powerful systems and leverage their full potential in creating accurate, clash-free, and well-documented plant designs.

Related Posts

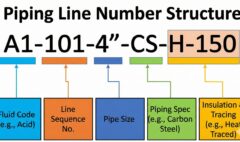

Importance of Line Numbering in the Piping Design Process

December 4, 2025