The Gatekeepers of Steam: Pressure Design of Steam Traps Under EN 13480 🇪🇺💨

The Gatekeepers of Steam: Pressure Design of Steam Traps Under EN 13480 🇪🇺💨

Piping Engineering and Piping Design

Description: Steam traps are the unsung heroes of thermal efficiency, but their failure can be catastrophic. While many engineers are familiar with American standards, the European framework requires a different approach. This post breaks down the pressure design and selection verification of steam traps within piping systems governed by EN 13480 (Metallic Industrial Piping) and the Pressure Equipment Directive (PED). We will cover material selection, pressure-temperature ratings, and the critical calculation checks required for compliance.

The Role of the Steam Trap in the EN Piping System

In any steam network, the steam trap has a dual responsibility: thermodynamic efficiency (removing condensate and non-condensable gases) and mechanical integrity (holding back the pressure of live steam). Under the European standard EN 13480, a steam trap is generally treated as a piping component (specifically, an ancillary usually falling under the definition of valve/accessory).

Unlike a straight run of pipe where the engineer calculates the wall thickness from scratch, steam traps are often selected as standard components. However, the Piping Engineer is responsible for verifying that the trap’s design pressure and temperature ratings comply with the system requirements defined in EN 13480-3 (Design and Calculation).

1. The Regulatory Context: PED and EN 13480

Before diving into the math, it is crucial to understand that EN 13480 is a “Harmonized Standard.” This means that following it provides a “presumption of conformity” with the Pressure Equipment Directive (2014/68/EU).

For a steam trap, the design category (I, II, III, or IV) depends on:

Fluid Group: Steam is usually Group 2 (non-dangerous) unless pressures are extreme, but high-pressure steam can be treated with higher severity.

Pressure-Volume (PS x V) or Pressure-Diameter (PS x DN): The size and pressure determine the category and the level of inspection required.

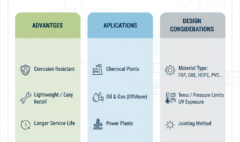

2. Material Selection: Speaking the EN Language

In the ASME world, we speak ASTM (A106, A216). In the EN 13480 world, we verify materials against EN 13480-2 (Materials).

For steam traps, which are typically cast or forged, you will encounter materials like:

Cast Steel: GP240GH (1.0619) – roughly equivalent to WCB.

Forged Steel: P250GH (1.0460) – roughly equivalent to A105.

Stainless Steel: X5CrNi18-10 (1.4301) – roughly equivalent to 304.

Critical Note: EN 13480-2 requires that materials have sufficient ductility and impact energy (typically ≥ 27J at 20°C or the lowest scheduled operating temperature).

3. Pressure Design Verification

While manufacturers often design the trap body according to EN 12516 (Industrial Valves – Shell Design Strength), the piping engineer must verify the integration using EN 13480-3.

A. The Pressure-Temperature (P-T) Rating Check

Most steam traps usually utilize standard flanges (EN 1092-1) or welded ends. The simplest verification is ensuring the maximum operating condition falls within the P-T rating curve of the component.

However, if the trap has a custom body or welded ends that become part of the piping pressure envelope, you may need to verify the wall thickness using the cylindrical shell formula from EN 13480-3, Section 6:

Where:

$latex e$ : Required nominal wall thickness (analysis thickness + allowances).

$latex P_c$ : Calculation pressure (Design pressure).

$latex D_o$ : External diameter of the component body.

$latex f$ : Allowable stress of the material at design temperature (derived from EN 13480-3 Section 5).

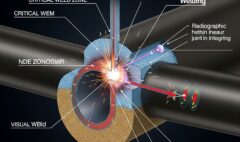

$latex z$ : Joint coefficient (1.0 for seamless bodies, usually 0.85 or 1.0 for welded depending on NDT).

B. Corrosion Allowance ( $latex c0 $ )

Steam condensate can be highly corrosive (carbonic acid). EN 13480 requires the designer to add a corrosion allowance to the calculated thickness.

For steam condensate lines, a minimum corrosion allowance ($latex c_0$) of 3.0 mm is often recommended unless the material is corrosion-resistant (like stainless steel).

4. Proof Test (Hydrostatic Test)

According to EN 13480-5 (Inspection and Testing), the installed steam trap must withstand the system pressure test. The standard hydrostatic test pressure ($P_{test}$) is calculated as the higher of:

- $latex P_{test} = 1.25 \cdot P_c \cdot \frac{f_{test}}{f}$

- $latex P_{test} = 1.43 \cdot P_c$

Where $latex f_{test}$ is the allowable stress at test temperature (ambient) and $latex f$ is allowable stress at design temperature. The steam trap internals (bellows, floats) must either be able to withstand this pressure or be removed/isolated during the test.

5. Installation and Safety (EN 13480-3)

The design isn’t just about the trap body; it’s about the assembly.

Isolation: EN 13480 mandates the ability to isolate components for maintenance.

Strainers: To protect the valve seat from erosion (which compromises pressure containment), upstream strainers are standard practice.

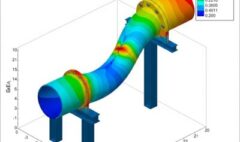

Thermal Expansion: Steam lines expand significantly. The trap assembly branch piping needs flexibility analysis to ensure the nozzle loads on the trap do not crack the connection welds.

Courses to Learn

To master the design of steam traps and piping systems under European norms, the following courses are recommended:

EN 13480 Metallic Industrial Piping – Design and Calculation: A comprehensive deep dive into Part 3 of the standard.

PED 2014/68/EU Awareness: Understanding the legal requirements for pressure equipment in Europe.

Steam System Engineering & Design: specialized course focusing on condensate loops, trap selection, and fluid dynamics.

Material Selection for European Piping Projects: Understanding EN material designations and equivalents.