The Silent Sentinels: How Pipe Numbering Safeguards Industrial Operations

The Silent Sentinels: How Pipe Numbering Safeguards Industrial Operations

Introduction

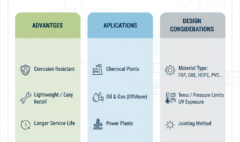

In the complex world of industrial facilities, from chemical plants to refineries, a vast network of piping acts as the circulatory system, transporting fluids and gases that are often hazardous. While the focus is frequently on the major equipment like pumps and reactors, the humble pipe plays a critical, yet often overlooked, role in overall safety and risk management. A key element of this is a robust and standardized system for pipe numbering.

The Chaos of the Unlabeled

Imagine a sprawling industrial plant with thousands of meters of interconnected pipes. Without a clear system of identification, this network can become a labyrinth of confusion.

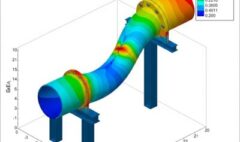

As illustrated in the diagram above, a lack of clear labeling can lead to significant risks. In an emergency, like a leak or a fire, response teams could waste precious time trying to identify which pipe is carrying a hazardous substance. This delay can escalate a manageable incident into a catastrophic event.

Pipe Numbering: A Pillar of Safety

A well-implemented pipe numbering system is not just about organization; it is a fundamental safety measure. Here’s why:

- Hazard Identification: Each pipe number is typically tied to a line list or a P&ID (Piping and Instrumentation Diagram) that contains vital information. This includes the fluid’s service, its pressure, temperature, and material of construction. By knowing the pipe number, an operator or safety engineer can instantly access this data, allowing them to understand the potential hazards associated with that specific line.

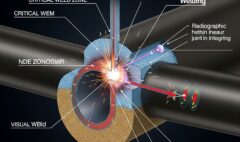

- Emergency Response: In a crisis, time is of the essence. A clear pipe numbering system allows emergency responders to quickly isolate the source of a leak or a fire. They can immediately identify the contents of a pipe and take appropriate measures, such as shutting off a specific valve, without having to trace lines back to their source.

- Maintenance and Inspection: Routine maintenance and statutory inspections are crucial for preventing failures. A unique pipe number ensures that the correct line is being inspected or repaired. It prevents errors like opening the wrong flange or cutting into a live line, which could have disastrous consequences. It also allows for the tracking of a pipe’s history, including past repairs, inspections, and corrosion rates.

- Process Safety Management (PSM): For facilities covered under PSM regulations, accurate and up-to-date piping information is a legal requirement. Pipe numbering is the link that connects the physical asset in the field to the engineering documentation (like P&IDs and isometric drawings), which is essential for process hazard analyses (PHAs) and management of change (MOC) procedures.

The Anatomy of a Good Pipe Number

A good pipe number is not just a random sequence of characters. It is a structured code that provides immediate information. A common structure might include:

- Area Code: Indicates the physical location within the plant.

- Service Code: Identifies the fluid being transported (e.g., “STM” for steam, “ACD” for acid).

- Sequence Number: A unique identifier for that specific line.

- Pipe Size: The diameter of the pipe.

- Pipe Specification: The material and pressure rating of the pipe.

This structured approach ensures that even without looking up a drawing, a trained operator can glean critical information just by reading the pipe’s label.

As shown in this diagram, a well-labeled pipe provides immediate clarity, contrasting sharply with the unlabeled system shown earlier.

Conclusion

In conclusion, pipe numbering is not a mundane administrative task. It is a critical component of a comprehensive safety and risk management program. By providing a clear and unambiguous way to identify every line in a facility, it empowers operators, maintenance personnel, and emergency responders to make informed decisions, preventing accidents and protecting both people and assets. In the high-stakes world of industrial operations, a simple number on a pipe can be the difference between a minor incident and a major disaster.