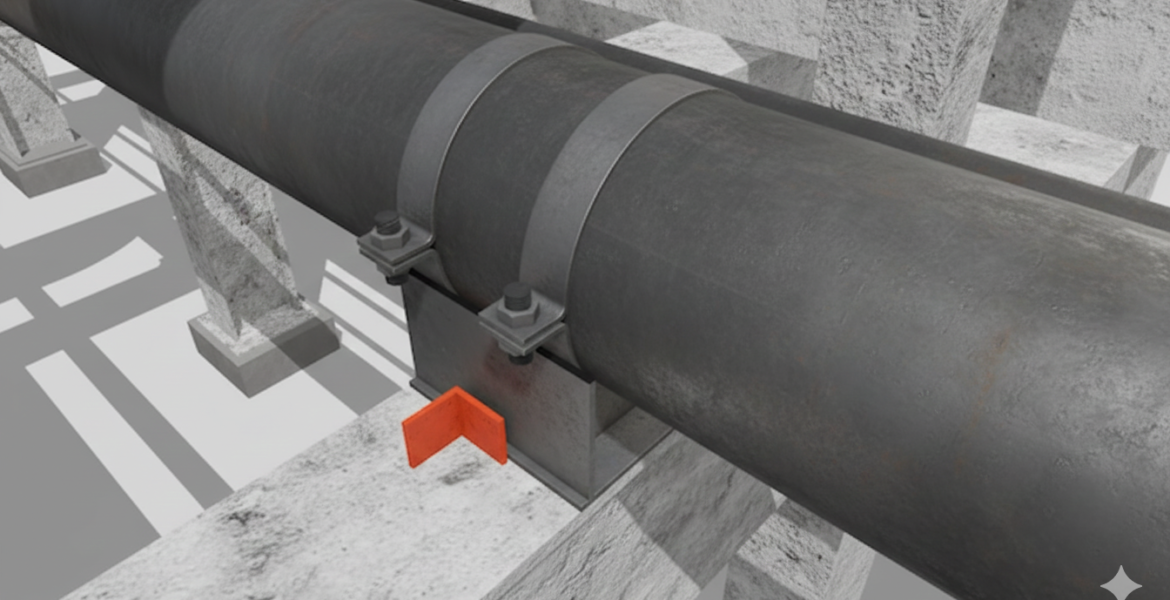

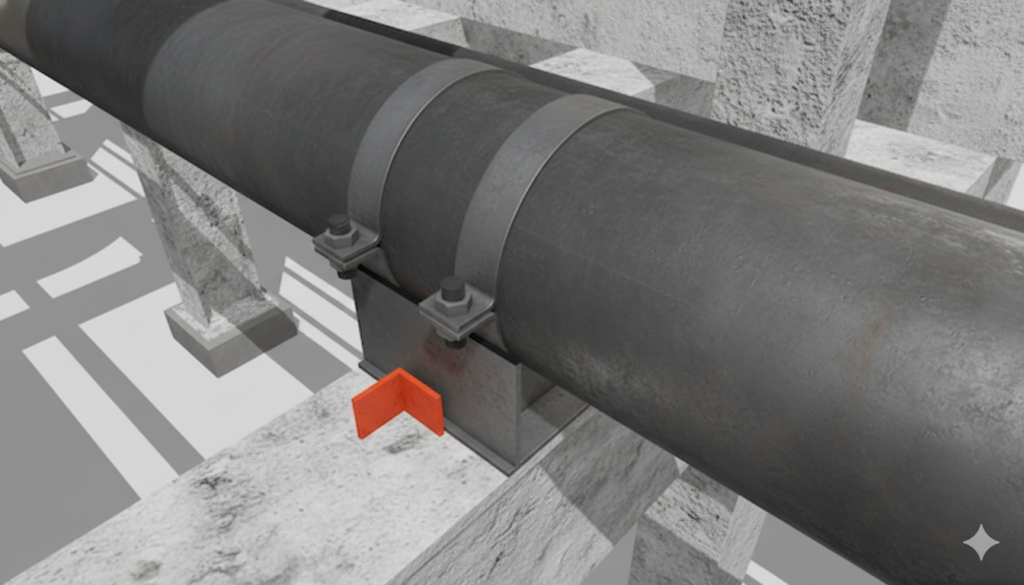

The Pipe Guide: Steering the Energy

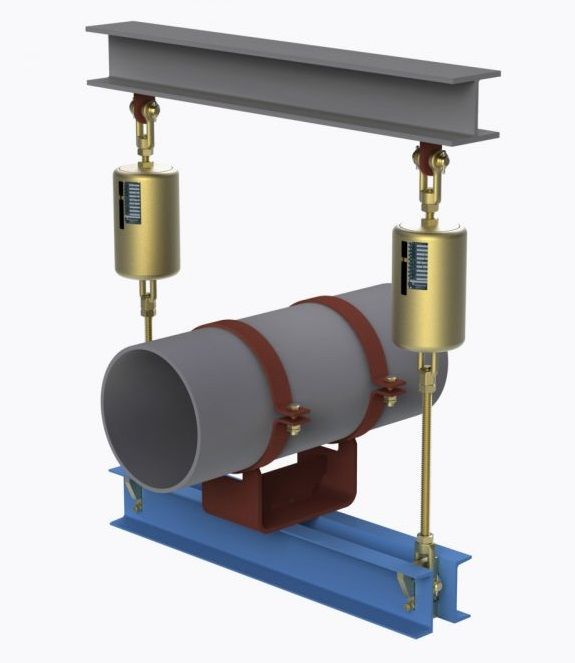

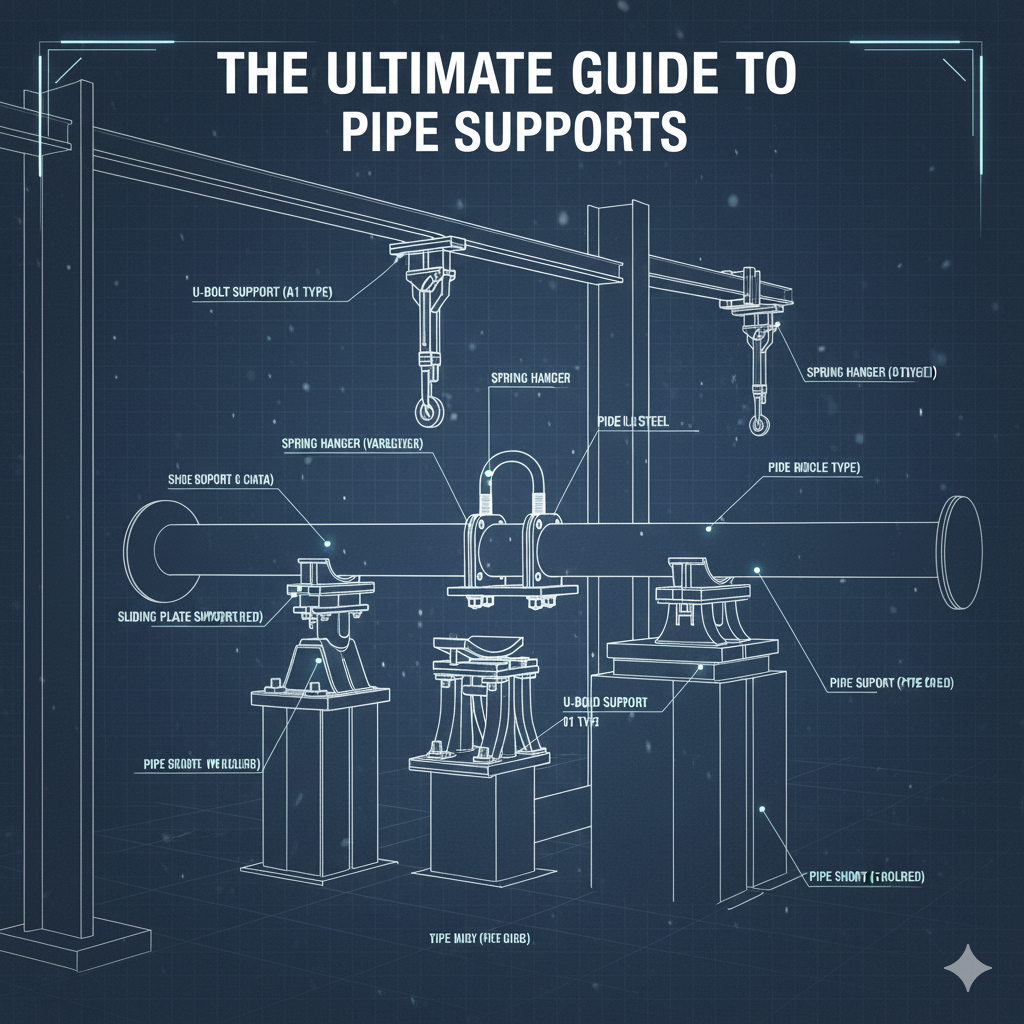

Pipe Supports

1. Definition & Function Deep Dive

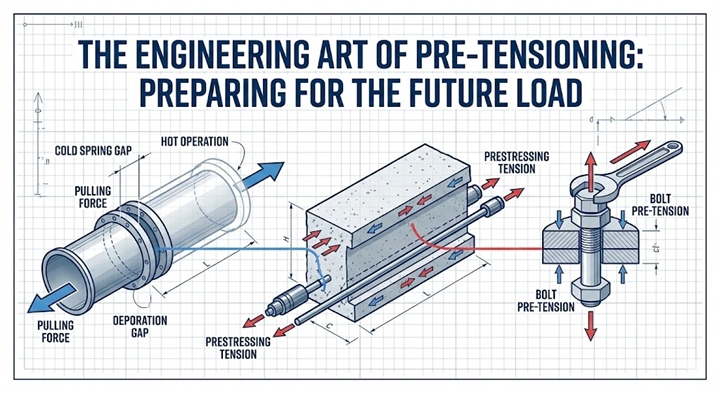

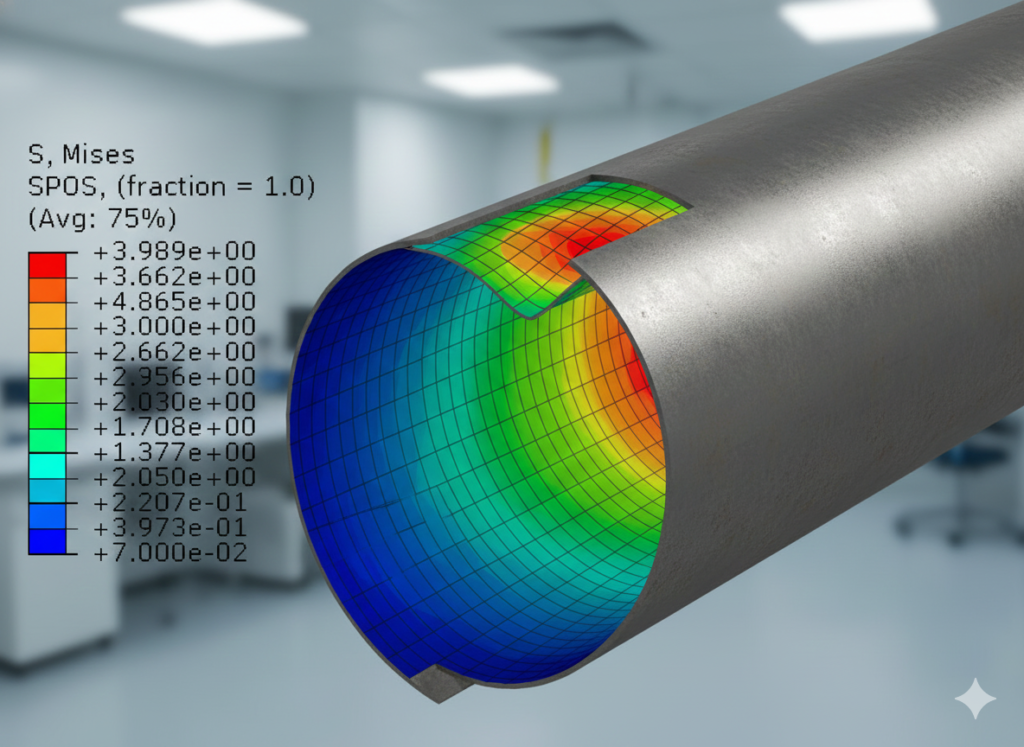

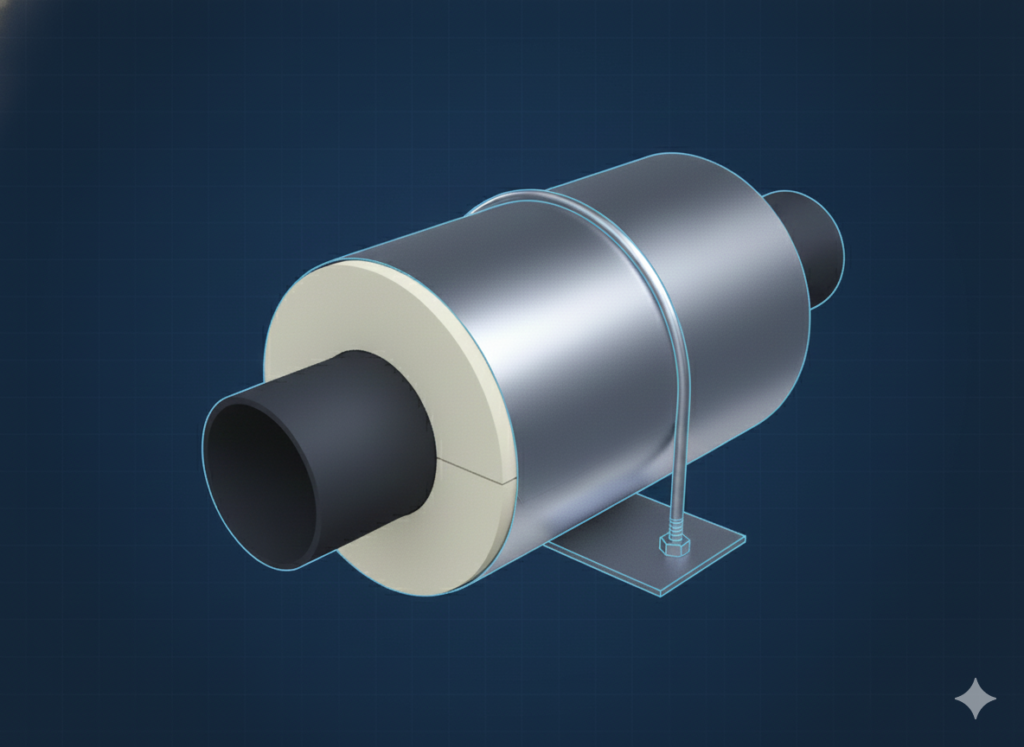

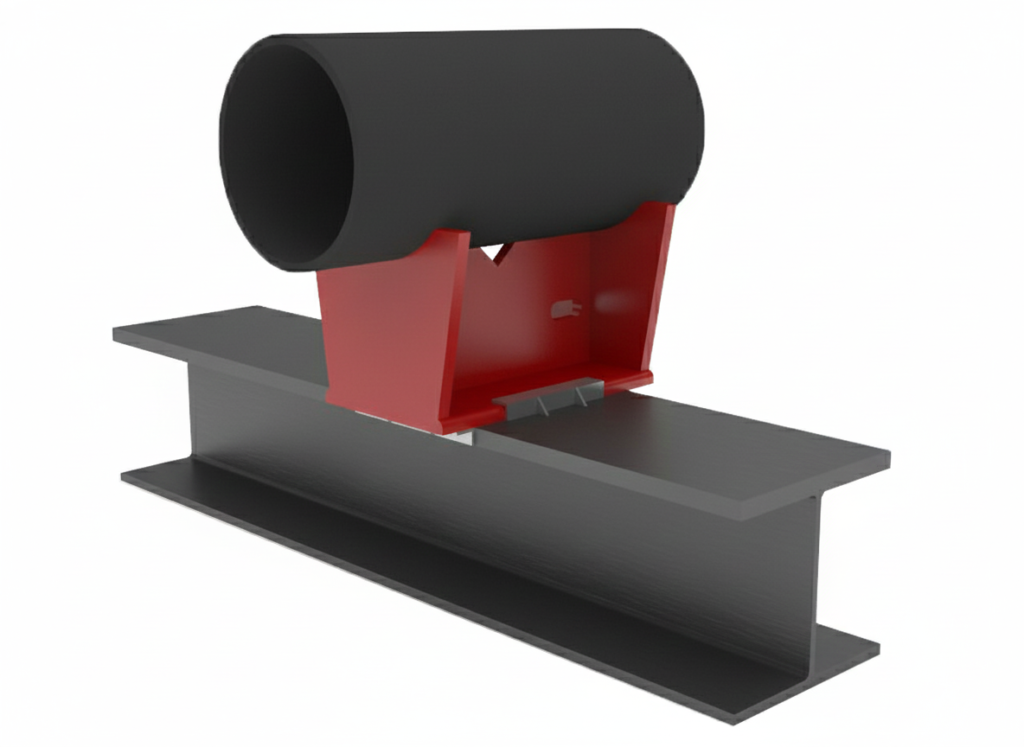

When a long pipe heats up, it wants to grow. Like trying to push a rope, if you compress a long pipe without confining it, it will buckle or bow sideways instead of moving straight into an expansion loop. A guide forces the axial thermal expansion to go exactly where the designer intended.

2. The Importance of Spacing (The “L/r” Ratio)

Piping engineers calculate guide spacing based on the Euler column buckling formula. Hotter, smaller diameter pipes need guides spaced much closer together than cooler, larger, stiffer pipes to prevent buckling.

3. Troubleshooting: When Guides Bind

The most common failure of a guide is “binding.”

- The Cause: If the pipe twists slightly during installation, or if the guide is installed too tightly without proper clearance gaps, friction takes over. When the pipe heats up, it wedges itself in the guide instead of sliding through it.

- The Result: The guide inadvertently becomes an anchor. The thermal forces build up until something breaks—usually the guide structure itself welds rip apart, or the pipe bows severely between guides.

- The Fix: For heavy or large pipes, use PTFE (Teflon) slide plates lining the guide box to ensure low friction.

Comment (1)

Sherif Mokhtar

Very valuable article, thanks for sharing