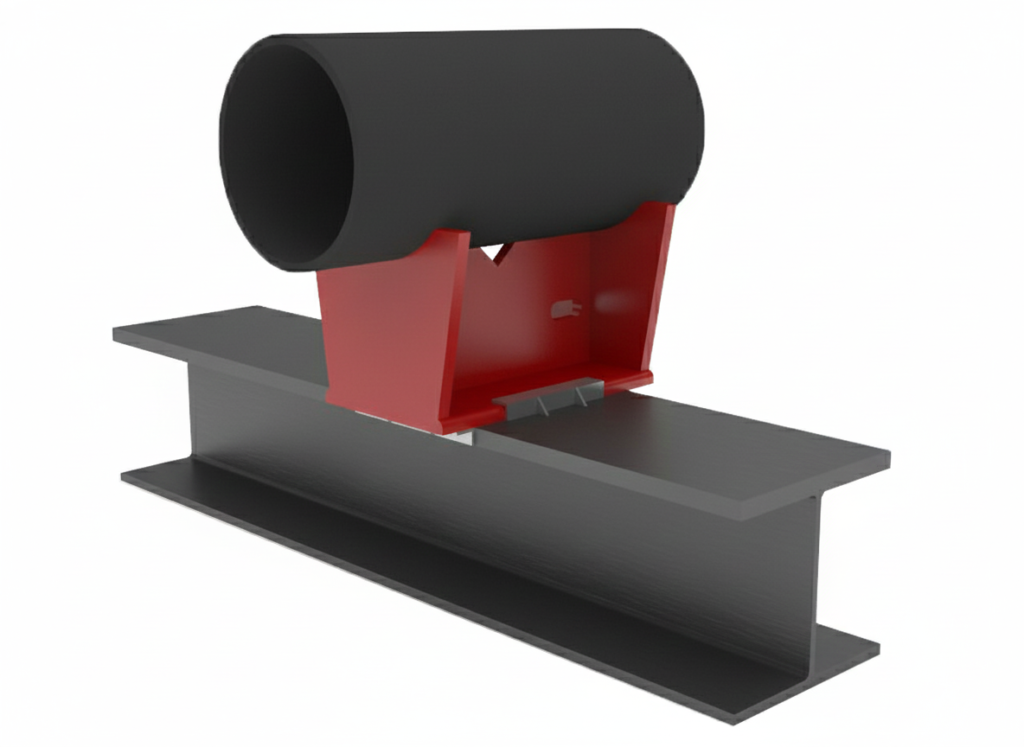

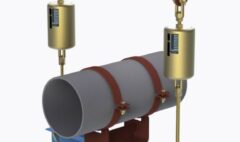

The Pipe Saddle (Wear Pad): The Sacrificial Shield

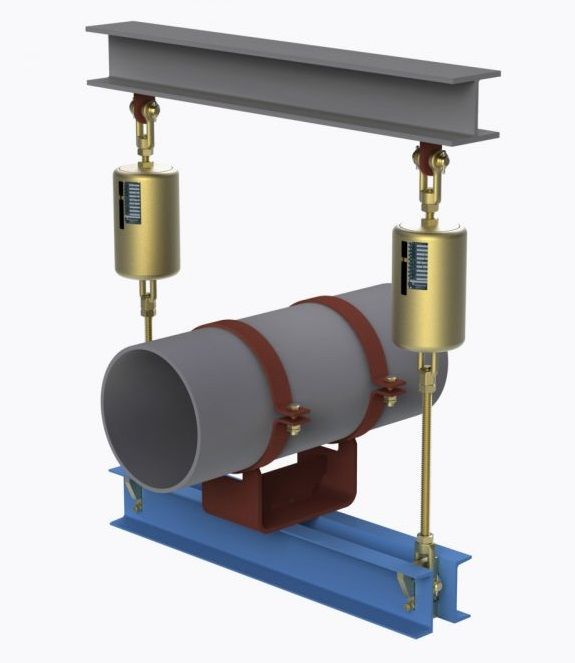

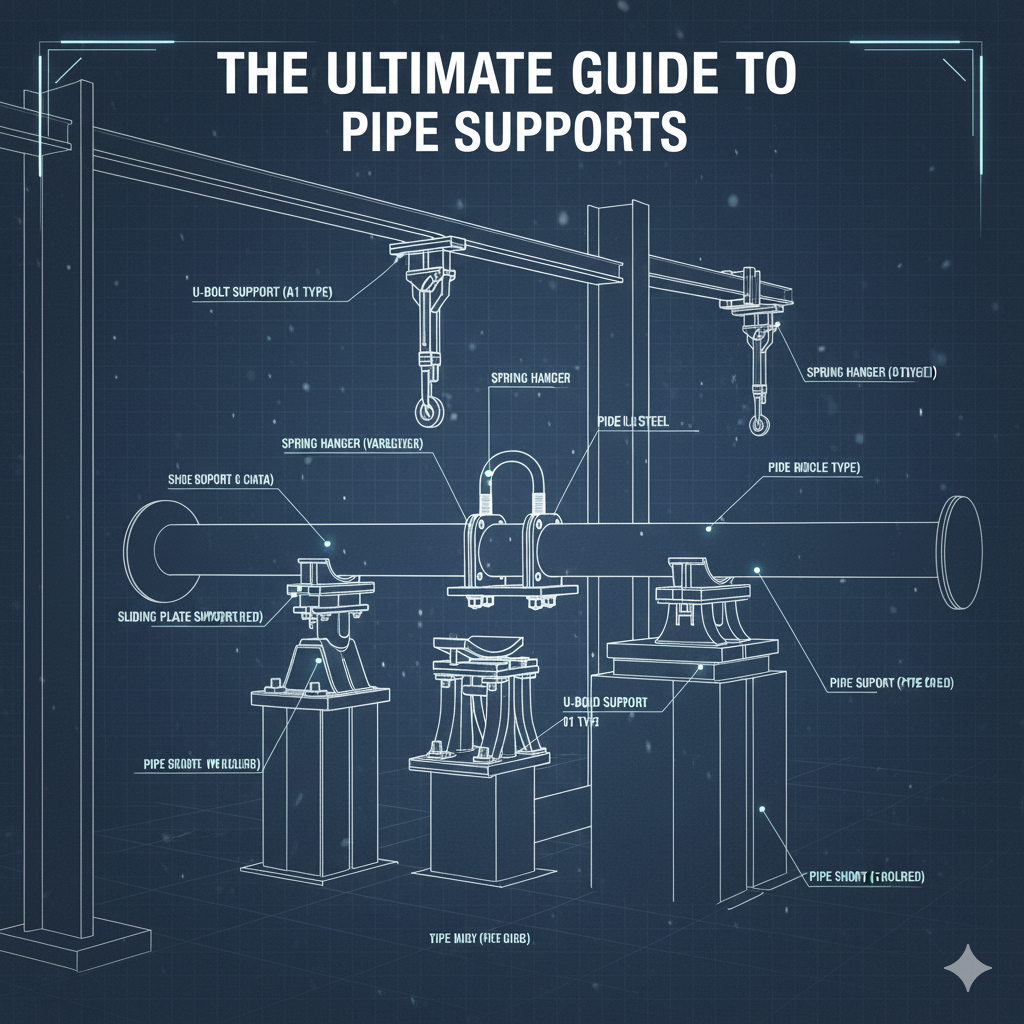

Pipe Supports

1. Definition & Function Deep Dive

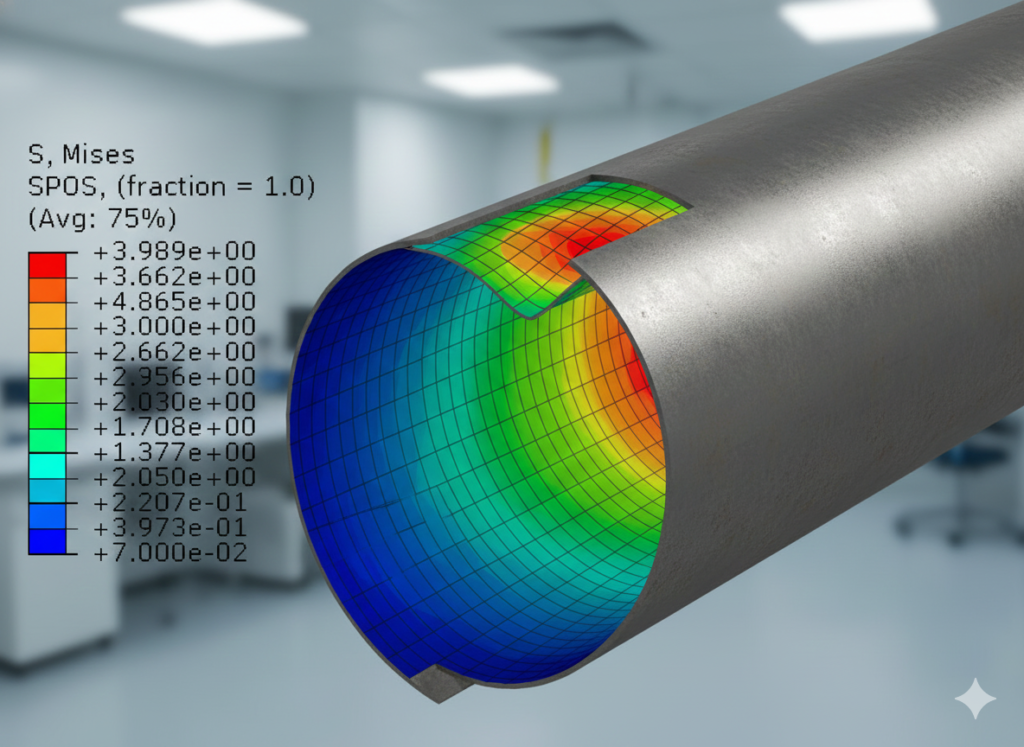

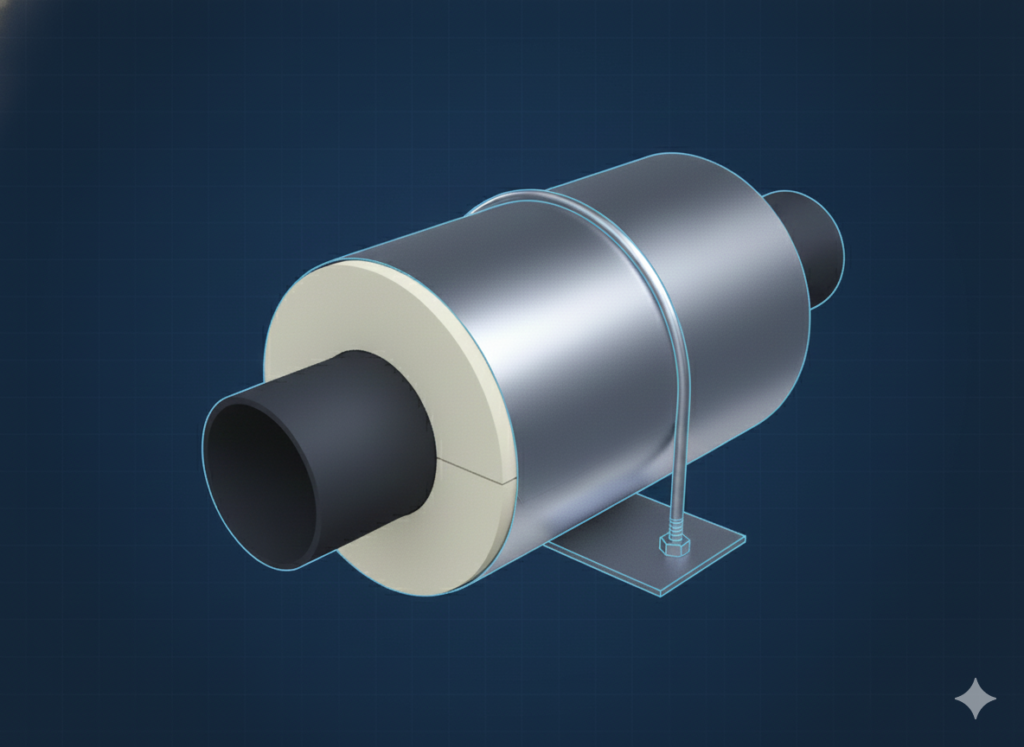

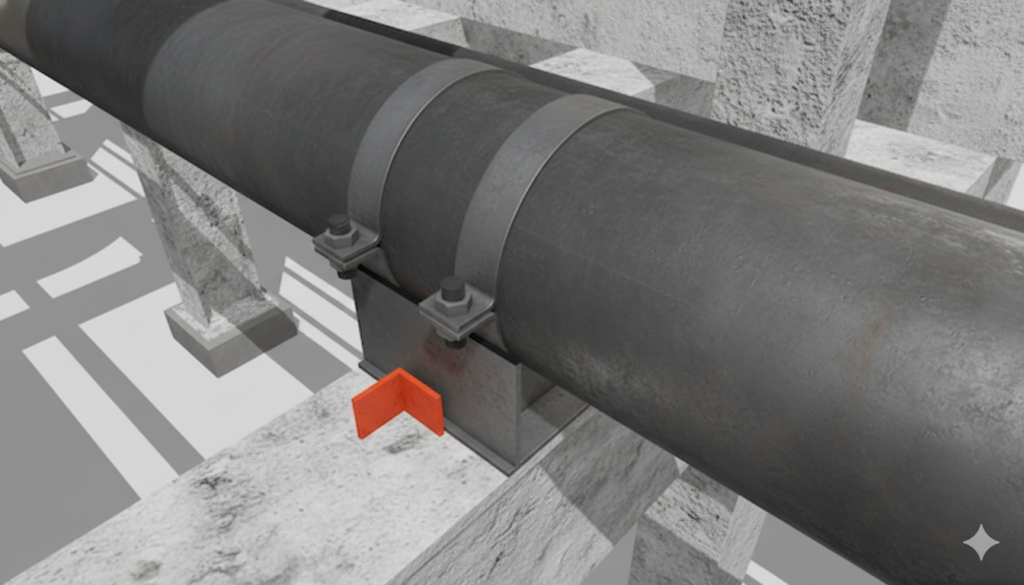

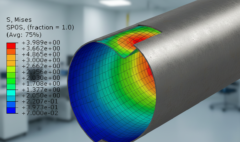

When a large, heavy pipe sits directly on concrete or steel, the point-loading stresses at the bottom of the pipe can be enormous. Furthermore, as the pipe expands and contracts, it rubs back and forth. A saddle is a sacrificial plate welded to the bottom of the pipe to take this abuse, protecting the pressure boundary of the actual pipe.

2. Material & Fabrication Physics

- Matching Material: The saddle must match the pipe metallurgy. Welding a carbon steel pad to a stainless-steel pipe creates a massive galvanic corrosion cell, eating away the stainless pipe rapidly.

- Thickness: The pad is usually the same thickness or slightly thinner than the pipe wall itself.

3. Installation & The “Weep Hole” Debate

A saddle is typically fillet welded all around its perimeter to seal it against moisture entry.

- The Problem: During welding, the air trapped between the saddle and the pipe heats up and expands dramatically, potentially blowing out the final weld pass.

- The Solution (The Weep Hole): Fabricators drill a small hole in the center of the pad to let this air escape during welding.

- The Controversy: Some specifications require plugging this hole with grease or silicone after welding to keep water out. Others demand it be left open so any moisture that does get in can drain out. The “plug it” camp usually wins in offshore environments.