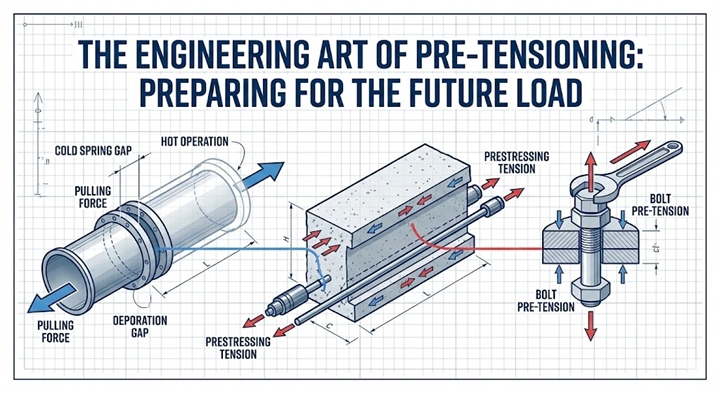

The Engineering Art of Pre-Tensioning: Preparing for the Future Load

In many engineering disciplines, the state of a system during installation (the “cold” condition) is drastically different from its state during operation. To ensure optimal performance and longevity, engineers often employ a clever strategy: applying a pre-calculated initial load or strain in the opposite direction of the expected operational forces. This technique, known as pre-tensioning or pre-loading, effectively “programs” the system to reach a neutral or low-stress equilibrium when it’s actually doing its job.

Here is an expanded look at how this vital concept is applied across different fields.

1. High-Temperature Piping: The “Cold Spring”

In power plants and refineries, pipes carry fluids at extremely high temperatures. As the pipe heats up, it expands significantly. If this expansion is restricted, it creates massive forces that can damage expensive equipment like pumps and turbines connected to the pipe ends.

To counteract this, piping engineers use a technique called Cold Springing.

- The Concept: The pipe is intentionally fabricated slightly shorter than the actual distance between its connection points.

- The Action: During installation (the “cold” state), the pipe ends are mechanically pulled together to close the gap and bolted into place. This introduces an initial tensile stress into the piping system.

- The Result: As the system heats up during operation, the pipe expands. This thermal expansion relieves the initial pre-tension. At its full operating temperature, the pipe reaches a state of near-zero stress on the equipment nozzles, having grown into its intended position.

2. Structural Engineering: Prestressed Concrete

Concrete is an incredibly strong material under compression (being pushed together) but relatively weak under tension (being pulled apart). A standard concrete beam will crack on its bottom side when a heavy load is placed on top, as it bends and the bottom fibers are stretched.

To overcome this limitation, structural engineers create Prestressed Concrete.

- The Concept: Before the concrete is even poured, high-strength steel cables (tendons) are placed inside the mold and stretched tight using hydraulic jacks.

- The Action: The concrete is poured around these tensioned cables and allowed to harden. Once cured, the jacks released. The cables try to shrink back to their original length, but they are bonded to the concrete.

- The Result: This massive internal force compresses the entire concrete beam. When a service load (like a car on a bridge) is applied, it tries to bend the beam and create tension. However, it must first overcome the immense pre-existing compression. The concrete remains in its strong, compressed state, significantly increasing the beam’s load-carrying capacity and preventing cracking.

3. Mechanical Fastening: The Bolted Joint

Perhaps the most common example of pre-tensioning is the simple act of tightening a bolt and nut. A bolted joint does not work simply by having a pin through a hole; it works by creating a clamping force.

- The Concept: A bolt acts like a very stiff spring.

- The Action: When you tighten a nut with a wrench, you are actually stretching the bolt slightly. This stretch is the “pre-tension.”

- The Result: The stretched bolt acts like a compressed spring trying to pull itself back together. This creates an equal and opposite clamping force that squeezes the two parts of the joint together. For the joint to separate, an external force must be applied that is greater than this initial clamping force. Without proper pre-tension (torquing), the joint would quickly loosen under vibration or external loads.