Piping Project Management: From Concept to Completion 🏁

Piping Project Management: From Concept to Completion 🏁

Introduction

Introduction: What is piping project management? Unique challenges in piping projects (complexity, interdependencies, material lead times).

Phases of a Typical Piping Project:

- Conceptualization/Feasibility: Defining scope, initial estimates.

- Front-End Engineering Design (FEED): Developing P&IDs, preliminary layouts, major equipment sizing, more refined cost estimates. Deliverables: Basis of Design, preliminary P&IDs, plot plan.

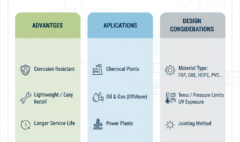

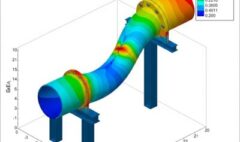

- Detailed Design & Engineering: Finalizing P&IDs, 3D modeling, stress analysis, isometric generation, material specifications, support design. Deliverables: Approved P&IDs, 3D model, stress reports, Isometrics, MTOs, GA drawings. ASME B31.3 compliance is a key design output.

- Procurement: Sourcing pipes, fittings, valves, specialty items. Long-lead items. Vendor management.

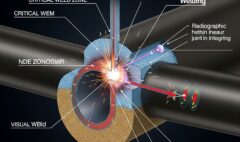

- Fabrication & Construction: Shop and field fabrication, erection, support installation, NDE, pressure testing (ASME B31.3 Chapter VI).

- Commissioning: System cleaning, leak testing, reinstatement, pre-startup safety review (PSSR), startup.

Key Project Management Knowledge Areas in Piping:

- Scope Management: Defining and controlling what is and isn’t in the project.

- Schedule Management: Developing realistic timelines, critical path analysis, managing delays.

- Cost Management: Estimation, budgeting, cost control, earned value management.

- Quality Management: Ensuring design and construction meet specifications and codes (e.g., ASME B31.3 quality requirements). Inspection and Test Plans (ITPs).

- Resource Management: Allocating engineers, designers, welders, materials.

- Communication Management: Effective information flow between stakeholders.

- Risk Management: Identifying, analyzing, and mitigating potential piping project risks (e.g., material delays, design errors, site clashes).

- Stakeholder Management: Interacting with client, vendors, construction teams, regulatory bodies.

Interdisciplinary Coordination:

Critical role of the piping project manager/lead in coordinating with Civil/Structural, Mechanical (Equipment), Electrical, Instrumentation, Process.

Tools and Techniques

Project management software (Primavera, MS Project), 3D model reviews, progress tracking.

Conclusion & Call to Action

Successful piping projects demand strong technical knowledge and project management acumen. Courses on project management specifically tailored for engineering projects, including aspects of EPC (Engineering, Procurement, Construction) workflows, can equip piping professionals with the skills to deliver projects on time, within budget, and to the required quality standards.

Comments (2)

abdelkarim bouabdallah

I really appreciate this great summary—thanks a lot!

Mahmoud Abdallah

Thanks, please share to your colleagues who may need to read it