Selecting the Right Pipe Supports: Types, Functions, and Design Considerations 🛠️

0 comments

Selecting the Right Pipe Supports: Types, Functions, and Design Considerations 🛠️

Introduction:

Why are pipe supports crucial? They manage weight, control movement, and absorb loads, protecting the piping and connected equipment.

Functions of Pipe Supports:

- Carry deadweight (pipe, fluid, insulation).

- Accommodate or restrain thermal expansion/contraction.

- Control vibration.

- Absorb occasional loads (wind, seismic).

- Prevent excessive pipe sag.

- Protect nozzles of connected equipment.

Common Types of Pipe Supports and Their Applications (with diagrams/images):

Rigid Supports:

- Rest Supports: Simple rests carrying vertical load, allowing axial movement (e.g., shoe, saddle).

- Anchor Supports: Fix the pipe in all directions (translation and rotation) at a specific point.

- Guide Supports: Restrain lateral movement while allowing axial movement.

Flexible Supports (Spring Supports):

- Variable Effort Springs: Support force varies with displacement. Used where thermal movement is moderate.

- Constant Effort Springs: Support force remains constant through a range of travel. Used for large vertical movements.

Other Support Types:

- Hangers (Rod Hangers): Suspend pipe from above.

- Snubbers (Shock Absorbers): Allow slow thermal movement but lock up under sudden dynamic loads (seismic, PRV discharge).

- Sway Braces & Struts: Control vibration or sway.

- Shoes & Saddles: Protect pipe insulation, distribute load.

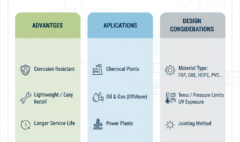

Design Considerations for Pipe Supports:

- Load Calculations: Deadweight, thermal loads, friction, occasional loads.

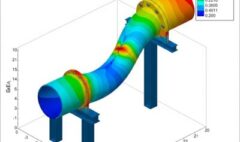

- Pipe Stress Analysis Inputs/Outputs: Support locations are determined iteratively with stress analysis. ASME B31.3 Para 321 provides general requirements for supports.

- Span Limitations: Maximum distance between supports to prevent sag and overstress. Based on pipe size, material, contents.

- Material Selection for Supports: Compatibility with pipe material, environmental conditions (corrosion).

- Thermal Expansion: How the support will accommodate or guide pipe movement. Selection of sliding surfaces.

- Standard vs. Special Supports: Using standard, pre-engineered supports vs. custom-designed ones.

- Weld-on vs. Clamp-on Supports.

ASME B31.3 Guidance on Supports:

- Para. 321: General requirements for piping supports.

- Appendix F (obsolete, but historical context) & MSS SP-58 (Manufacturers Standardization Society): Provides standard types and terminology.

- Stress analysis verifies adequacy of support scheme per B31.3 stress limits.

Conclusion & Call to Action:

Pipe support design is integral to overall piping system integrity. Incorrect support selection or placement can lead to failure. Courses focusing on pipe support design, selection, and the application of standards like MSS SP-58, combined with understanding stress analysis outputs per ASME B31.3, are essential for piping designers and engineers.

Related Posts

Key Responsibilities of a Piping Engineer 🏗️

December 19, 2025

Ensuring Integrity in Process Piping: Lessons from ASME B31.3

December 18, 2025

Future Trends in Piping Engineering

December 14, 2025