Nozzle Load Checks: Protecting Equipment Integrity in Piping Systems (API, WRC)

0 comments

Nozzle Load Checks: Protecting Equipment Integrity in Piping Systems (API, WRC)

Introduction:

- What are equipment nozzles? (Inlets/outlets on pumps, compressors, turbines, vessels, heat exchangers, tanks). Why piping loads on these nozzles are a major concern.

- Sources of Nozzle Loads:

- Pipe Weight: Sustained deadweight loads.

- Thermal Expansion/Contraction of Piping: Expansion loads causing forces and moments.

- Piping Misalignment during Installation.

- Vibration and Dynamic Loads (e.g., from PRV discharge, slug flow).

Consequences of Excessive Nozzle Loads:

- For Rotating Equipment (Pumps, Turbines, Compressors):

- Casing distortion, leading to misalignment of internal components (shaft, impeller, bearings).

- Increased vibration, premature bearing failure, seal leakage.

- Reduced efficiency and lifespan. Catastrophic failure in extreme cases.

- For Static Equipment (Vessels, Heat Exchangers, Tanks):

- High local stresses at the nozzle-shell junction.

- Shell distortion, cracking, leakage.

- Bolted flange joint leakage at the nozzle.

- For Rotating Equipment (Pumps, Turbines, Compressors):

Determining Allowable Nozzle Loads:

- Equipment Vendor Data Sheets/Drawings: This is the primary source. Vendors specify maximum allowable forces and moments for each nozzle.

- Industry Standards:

- API 610 (Centrifugal Pumps): Provides allowable nozzle loads for pumps (often conservative, vendor data preferred if more liberal and justified).

- API 617 (Centrifugal Compressors), API 618 (Reciprocating Compressors), API 611 (Steam Turbines), etc.

- NEMA SM 23 (Steam Turbines).

- Calculation Methods (for Vessels/Tanks when vendor data is unavailable):

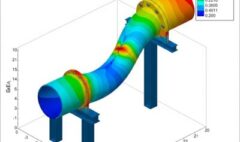

- WRC 107 (Welding Research Council Bulletin 107): Local Stresses in Spherical and Cylindrical Shells due to External Loadings.3 Used for individual nozzle loads.

- WRC 297 (Welding Research Council Bulletin 297): Similar to WRC 107 but for closely spaced nozzles or nozzles on vessel heads. (More recently, WRC 537 has superseded/updated parts of these for FEA validation).

- ASME Section VIII, Div 2, Part 5 (Design by Analysis): Can be used for detailed FEA if needed.

The Iterative Process of Nozzle Load Compliance:

- Pipe stress engineer calculates loads from piping onto nozzles.

- These calculated loads are compared to allowable.

- If loads exceed allowable:

- Modify piping layout (add flexibility, reroute).

- Adjust support scheme.

- Consider expansion joints (with caution).

- Discuss with equipment vendor (potential for higher allowables with justification or local reinforcement of nozzle).

Reporting Nozzle Loads:

- Clear documentation of calculated vs. allowable loads.

ASME B31.3 Connection:

- The code (Para 319.5) requires consideration of terminal limitations. While B31.3 ensures pipe stress is okay, it doesn’t directly provide equipment nozzle allowables; it points to the need to check them against manufacturer or other standards.

Conclusion & Call to Action:

- Protecting equipment nozzles is a critical deliverable of pipe stress analysis. It prevents costly damage and ensures plant reliability. Specialized training on equipment nozzle load analysis, application of API standards (e.g., API 610), and WRC bulletins (107/297/537), along with understanding how these interact with pipe stress software results, is essential for piping and mechanical engineers.

Related Posts

Key Responsibilities of a Piping Engineer 🏗️

December 19, 2025

Ensuring Integrity in Process Piping: Lessons from ASME B31.3

December 18, 2025

Future Trends in Piping Engineering

December 14, 2025