Corrosion Control in Piping Systems: Mechanisms, Prevention, and Material Choice 🛡️💧

0 comments

Corrosion Control in Piping Systems: Mechanisms, Prevention, and Material Choice 🛡️💧

Introduction:

- Corrosion as a major threat to piping integrity. Definition of corrosion. Economic and safety impacts.

Why Corrosion is a Problem in Piping:

- Wall thinning leading to loss of containment (leaks, ruptures).

- Reduced structural integrity, lower pressure rating.

- Contamination of process fluids.

- Blockage due to corrosion products.

- Increased maintenance and replacement costs.

- Safety hazards (release of flammable/toxic fluids).

Common Corrosion Mechanisms in Piping Systems :

- Uniform Corrosion (General Attack): Even thinning of the material surface (e.g., carbon steel in acidic water).

- Localized Corrosion:

- Pitting Corrosion: Small, deep pits (e.g., stainless steel in chloride environments).

- Crevice Corrosion: Occurs in stagnant areas, under deposits, or at gaskets.

- Galvanic Corrosion: Dissimilar metals in contact in a corrosive electrolyte. The more active metal corrodes.

- Environmentally Assisted Cracking (EAC):

- Stress Corrosion Cracking (SCC): Combined action of tensile stress and a specific corrosive environment (e.g., austenitic stainless steels in hot chlorides, carbon steel in caustic or amine service).

- Hydrogen Induced Cracking (HIC) / Sulfide Stress Cracking (SSC): Issues in wet H2S environments (sour service), particularly for carbon and low alloy steels. NACE MR0175/ISO 15156 is a key standard here.

- Corrosion Fatigue: Cyclic stresses in a corrosive environment.

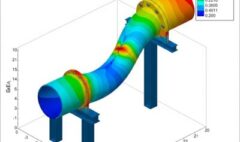

- Flow-Influenced Corrosion:

- Erosion-Corrosion: Mechanical removal of protective films by high-velocity or particle-laden flow, exposing fresh metal to corrosion.

- Impingement Attack: Localized erosion-corrosion due to direct impact of fluid.

- High-Temperature Corrosion: Oxidation, sulfidation, carburization at elevated temperatures.

- Microbiologically Influenced Corrosion (MIC): Corrosion caused or accelerated by microorganisms.

Corrosion Prevention and Control Strategies:

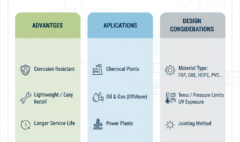

- Material Selection: The primary defense.

- Choosing materials inherently resistant to the process environment (e.g., stainless steels, nickel alloys, non-metallics).

- ASME B31.3 Chapter III emphasizes owner’s responsibility for selecting materials suitable for the fluid service.

- Protective Coatings & Linings:

- External coatings (paint, fusion-bonded epoxy) to prevent atmospheric or soil corrosion.

- Internal linings (rubber, cement, plastic) to protect from process fluid.

- Cathodic Protection:

- For buried or submerged carbon steel piping. Sacrificial anodes or impressed current systems.

- Corrosion Inhibitors: Chemicals added to the process fluid to reduce corrosion rate.

- Process Control: Modifying pH, temperature, velocity, removing oxygen or aggressive species.

- Design Considerations: Avoiding crevices, dead legs, low points where water can collect, dissimilar metal joints (or isolating them). Ensuring proper drainage.

- Material Selection: The primary defense.

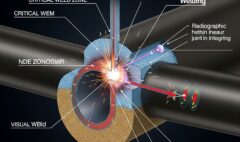

Corrosion Monitoring Techniques:

- Weight loss coupons, electrical resistance (ER) probes, linear polarization resistance (LPR) probes, ultrasonic testing (UT), intelligent pigging.

Role of ASME Codes and Industry Standards:

- ASME B31.3: Emphasizes material selection for corrosion resistance but relies on the owner/designer’s expertise. Provides corrosion allowance guidelines.

- API 570 (Piping Inspection Code): Guides inspection for corrosion and setting retirement thicknesses.

- NACE International (now AMPP) Standards: Provide extensive guidance on corrosion control, material selection for specific environments (e.g., NACE MR0175/ISO 15156 for sour service).

Conclusion & Call to Action:

- Corrosion is a persistent enemy of piping systems. Understanding its mechanisms and implementing effective control strategies is crucial for safety and asset longevity. Specialized courses on corrosion engineering, material selection for corrosive environments, and relevant standards like NACE MR0175 and API 570 are essential for engineers tasked with designing and maintaining durable piping infrastructure.

Related Posts

Key Responsibilities of a Piping Engineer 🏗️

December 19, 2025

Future Trends in Piping Engineering

December 14, 2025