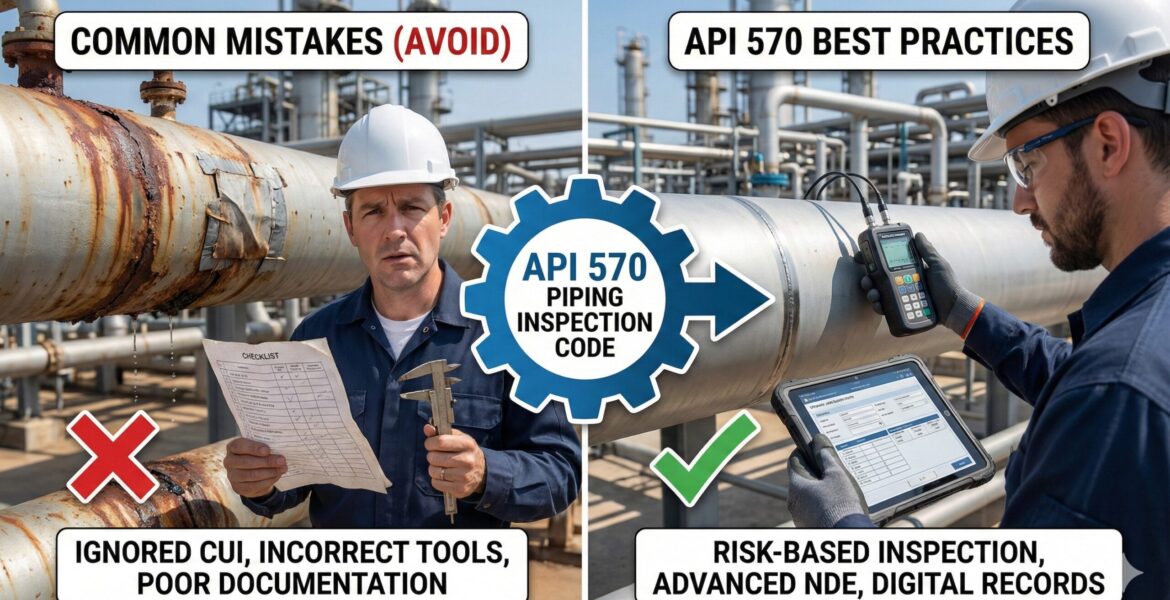

Avoiding Common Mistakes in Piping Inspection (API 570)

Avoiding Common Mistakes in Piping Inspection (API 570)

Introduction

Industrial piping systems are the lifelines of refineries, petrochemical plants, and power stations. Their reliability directly affects safety, environmental compliance, and operational continuity. The API 570 Piping Inspection Code provides a structured framework for inspection, repair, alteration, and rerating of piping systems. Yet, despite its clarity, many organizations fall into recurring mistakes that compromise both compliance and workplace dignity.

This article explores these pitfalls in depth, offering practical guidance for inspectors, engineers, and managers. By the end, you’ll see how technical rigor under API 570 is not just about compliance — it’s about respect for workers, communities, and the integrity of engineering practice.

1. Inadequate Thickness Measurement

The Problem

A common shortcut in inspection programs is reliance on single-point ultrasonic thickness readings. While convenient, this approach overlooks localized corrosion, erosion, and pitting.

Consequences

- Hidden risks: Localized thinning can lead to sudden leaks or ruptures.

- Regulatory exposure: Incomplete data may fail audits or investigations.

- Workplace dignity: Workers exposed to unsafe piping conditions feel undervalued.

Best Practices

- Implement grid-based ultrasonic mapping to capture variations.

- Use statistical analysis to identify corrosion trends.

- Adopt digital record-keeping for traceability and transparency.

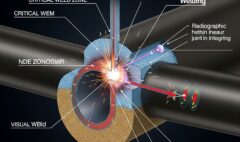

2. Overlooking Weld Quality

The Problem

Visual inspection alone is often considered sufficient. However, weld defects such as lack of fusion, porosity, or cracks remain undetected without advanced methods.

Consequences

- Structural failure: Weld cracks propagate under cyclic stress.

- Operational downtime: Weld failures can cause catastrophic shutdowns.

- Human impact: Unsafe welds endanger frontline workers.

Best Practices

- Employ radiographic testing (RT) or phased-array ultrasonic testing (PAUT).

- Train inspectors in weld defect recognition.

- Integrate weld inspection into routine maintenance schedules.

3. Misinterpretation of Corrosion Rates

The Problem

Linear extrapolation of corrosion rates is common, but environments rarely behave linearly. High-temperature, acidic, or turbulent zones accelerate degradation unpredictably.

Consequences

- Underestimation: Inspection intervals set too far apart.

- Unexpected failures: Accelerated corrosion leads to leaks.

- Cultural impact: Workers lose trust in inspection programs.

Best Practices

- Apply corrosion modeling software.

- Adjust inspection frequency based on operating conditions.

- Collaborate with corrosion specialists for accurate predictions.

4. Neglecting Documentation Standards

The Problem

Inspection reports often lack detail, consistency, or standardized formatting.

Consequences

- Audit challenges: Regulators struggle to verify compliance.

- Knowledge loss: Poor records hinder future teams.

- Respect gap: Workers feel their efforts are undervalued.

Best Practices

- Adopt standardized templates aligned with API 570.

- Use digital platforms for centralized record-keeping.

- Train teams on documentation best practices.

5. Disconnect Between Inspection and Operations

The Problem

Inspection teams often work in isolation from operations staff.

Consequences

- Missed insights: Operational anomalies go uncorrelated with inspection data.

- Reduced buy-in: Operators see inspection as a burden, not a partnership.

- Justice issue: Workers excluded from safety decisions feel disrespected.

Best Practices

- Conduct joint review sessions between inspectors and operators.

- Align inspection findings with maintenance planning.

- Foster a culture of collaboration across departments.

Conclusion

Avoiding these mistakes requires more than technical compliance — it demands a mindset of dignity, accountability, and collaboration. By strengthening inspection practices under API 570, organizations not only protect assets but also uphold workplace justice, ensuring that employees operate in safe, reliable environments.

API 570 is not just a code — it’s a commitment to integrity in engineering and respect for the people who make industrial plants run.