Flexibility Analysis and Expansion Loops: Managing Thermal Growth in Piping Systems 🔁

Flexibility Analysis and Expansion Loops: Managing Thermal Growth in Piping Systems 🔁

Introduction:

-

- What is thermal expansion/contraction in piping? Why unmanaged thermal growth is a problem (high stresses, large forces on equipment). The concept of piping flexibility.

Calculating Thermal Expansion:

-

- Formula: ΔL=α⋅L⋅ΔT

- ΔL: Change in length.

- α: Coefficient of thermal expansion for the pipe material (from ASME B31.3 Appendix A or material standards).

- L: Original length of the pipe segment.

- ΔT: Temperature difference (operating temp – installation temp).

Why Flexibility is Needed ?

-

-

To absorb this ΔL without overstressing the pipe or connected equipment.

-

Methods to Introduce Flexibility into Piping Systems:

-

- Utilizing inherent flexibility: Using changes in direction (elbows) to create natural flexibility.

- Expansion Loops: Purposefully adding U-bends, Z-bends, or more complex loop configurations.

- Design considerations for loops: Size, space required, pressure drop.

- Offsets: Similar to loops but can be simpler changes in routing.

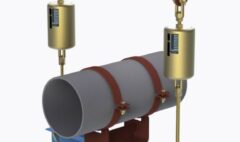

- Expansion Joints (Bellows, Slip-type, Ball Joints):

-

- When used: Space constraints, very large movements, isolating equipment.

- Types of expansion joints and their characteristics.

- Pros: Accommodate large movements in small spaces.

- Cons: Can be a weak point, potential for leaks, require careful selection and installation, may introduce pressure thrust issues if not anchored correctly. ASME B31.3 Appendix X provides guidance on expansion joints.

-

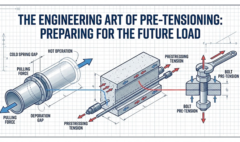

- Cold Spring / Pre-springing: Intentionally cutting pipes short or long to offset some thermal growth. Controversial, requires careful calculation and implementation. ASME B31.3 Para 319.2.4 discusses cold spring.

Stress Intensification Factors (SIFs) and Flexibility Factors:

-

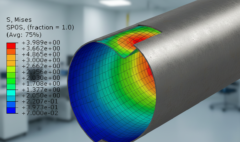

- Elbows and other fittings are more flexible than straight pipe and also experience higher stresses at localized points under bending.

- SIFs (ASME B31.3 Appendix D): Factors that multiply the nominal bending stress at a fitting to estimate the peak stress. Crucial for accurate stress calculation.

- Flexibility Factors (ASME B31.3 Appendix D): Factors that quantify how much more flexible a fitting is compared to straight pipe.

Performing Flexibility Analysis (as per ASME B31.3):

-

- Identifying systems requiring analysis (Para 319.4.1).

- Calculating the displacement stress range (SE).

- Comparing SE with the allowable displacement stress range (SA).

- Iterative process of routing, supporting, and analyzing.

Computer-Aided Flexibility Analysis:

-

- Using software like CAESAR II or AutoPIPE to model the system and calculate thermal stresses and movements.

Conclusion & Call to Action:

-

- Managing thermal expansion through proper flexibility analysis and design is fundamental to long-term piping integrity. Courses that delve into advanced flexibility analysis, SIF calculations, expansion loop design, and the nuanced application of ASME B31.3 (including Appendix D and Appendix X) are vital for stress engineers to prevent fatigue failures and protect equipment.