From Planning to Handover: The Complete Journey of Piping Construction 7/7

Piping Construction

Introduction: The Story We’ve Told

Over the past five posts, we’ve walked through the world of piping construction — from the invisible backbone of planning to the visible choreography of installation, from the tension of testing to the vigilance of safety.

Each stage is a chapter in a larger story: the story of how steel, standards, and human skill come together to create systems that carry energy, fluids, and trust.

The Five Pillars of the Journey

- Pre‑Construction & Planning

- The foundation of success.

- Material selection, drawing reviews, site surveys, and WPS approvals.

- Lesson: mistakes made in spreadsheets echo louder than those made in welds.

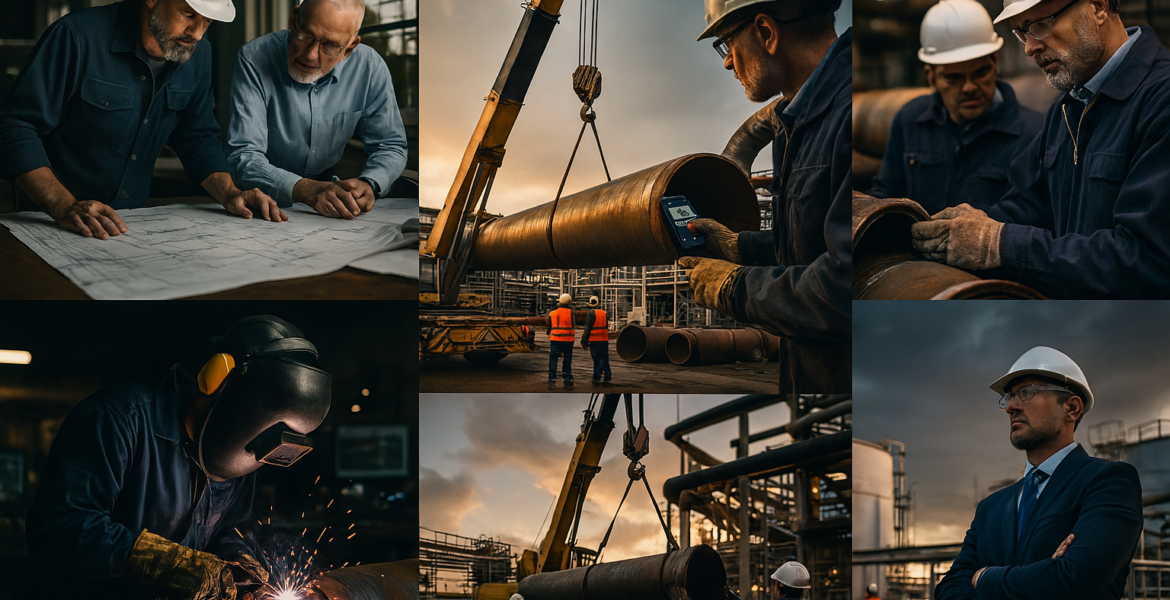

- Pipe Fabrication (Shop)

- Where design becomes reality.

- Cutting, beveling, welding, and NDT inspections.

- Lesson: precision in the shop prevents chaos in the field.

- Field Installation

- The most visible stage.

- Rigging, supports, flanges, valves, and tie‑ins.

- Lesson: installation is choreography — every misstep has consequences.

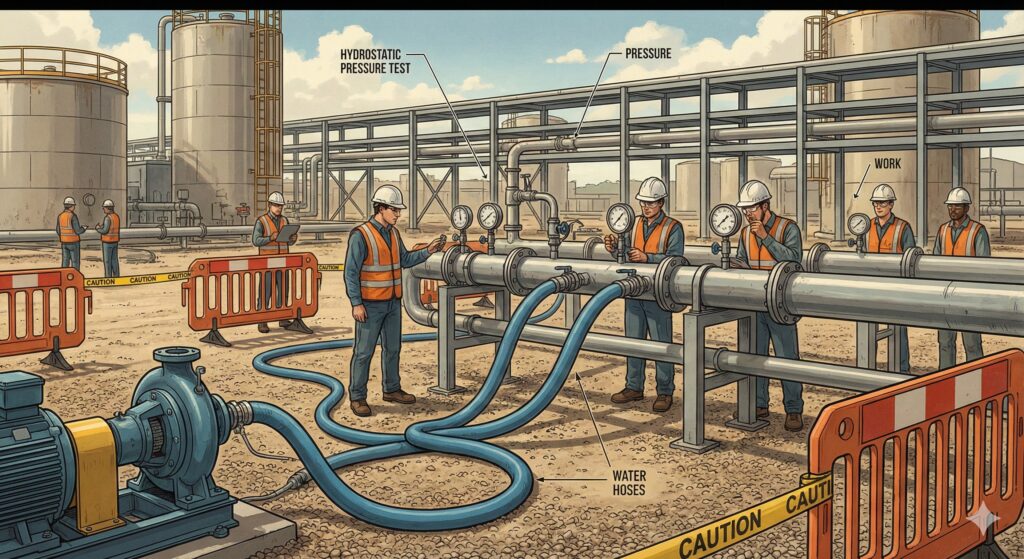

- Testing & Commissioning

- The moment of truth.

- Hydrotests, pneumatic tests, flushing, leak detection, reinstatement.

- Lesson: testing is not a formality — it is the guardian of integrity.

- Quality Control & Safety

- The final gatekeepers.

- Weld defect repair, dimensional control, hazard management, documentation.

- Lesson: safety and quality are not afterthoughts — they are the legacy.

Threads That Connect Them All

- Standards as Compass: ASME, API, ISO — guiding every decision.

- Documentation as Memory: weld logs, certificates, handover packages — the paper trail of trust.

- Human Stories as Lessons: welders, inspectors, riggers — each leaving fingerprints on the project.

On one site, a manager said, “We don’t build pipes. We build promises.” That sentiment runs through every stage.

Why This Journey Matters

For engineers, inspectors, and project managers, piping construction is more than technical steps. It’s a discipline of foresight, precision, and responsibility.

- Foresight in planning prevents costly rework.

- Precision in fabrication ensures fit and flow.

- Responsibility in installation protects lives and assets.

- Integrity in testing proves readiness.

- Vigilance in safety preserves trust.

Conclusion: The Legacy of Integrity

The journey of piping construction is not just about steel and welds. It’s about integrity — the invisible thread that runs from planning to handover.

When a system is commissioned, it carries more than fluids. It carries the discipline of engineers, the pride of welders, the vigilance of inspectors, and the responsibility of managers. That is the true legacy of piping construction: a promise kept, a system trusted, a story completed.