Fundamentals of Pipe Routing: Best Practices for Efficient and Safe Layouts 📐

0 comments

Fundamentals of Pipe Routing: Best Practices for Efficient and Safe Layouts 📐

Introduction:

What is pipe routing? More than just connecting Point A to Point B. It’s an art and science.

Core Principles of Good Pipe Routing:

- Safety: Maintain clearance for escape routes, access to safety equipment, avoid head knockers, minimize potential for leaks in sensitive areas.

- Operability & Maintainability: Ensure adequate access to valves, instruments, equipment for operation, inspection, and maintenance. Space for bolt removal, valve handle operation, equipment removal.

- Constructability: Ease of erection and installation. Minimize field welds, allow for hydrotesting and flushing.

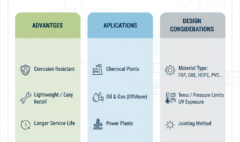

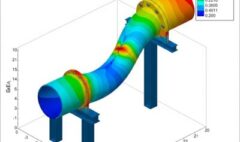

- Stress & Flexibility: Route pipes to naturally accommodate thermal expansion. Provide sufficient straight lengths for flowmeters. Avoid configurations that create high stress concentrations. This links to ASME B31.3 flexibility requirements.

- Supportability: Route pipes so they can be easily and economically supported. Consider standard support locations and types.

- Economy: Minimize pipe length, number of fittings, and complex configurations where possible (without compromising other principles).

- Process Requirements: Consider slope for gravity flow, avoid pockets in gas lines or high points in liquid lines prone to vapor lock, NPSH for pumps.

Developing Plot Plans and Equipment Layouts:

- How they influence piping routing strategies. Interdisciplinary coordination.

Routing in Congested Areas & Pipe Racks:

- Tiering of pipes (utilities, process lines, large bore, small bore). Expansion loops within racks. Crossing philosophy.

Specific Routing Considerations:

- Pump suction and discharge piping.

- Control valve station layout.

- Piping around columns, vessels, heat exchangers.

- Underground piping.

Common Pitfalls to Avoid:

- Dead legs, improper support leading to sag, clashing with structures/equipment, insufficient flexibility, obstructing access.

Use of 3D Modeling in Modern Pipe Routing:

- Visualizing routes, clash detection, optimizing space.

ASME B31.3 Considerations:

- While B31.3 doesn’t dictate exact routes, its requirements for flexibility (Chapter II, Part 5), supports (Para. 321), and design (Chapter II) heavily influence routing decisions to ensure stresses are within allowable limits.

Conclusion & Call to Action:

- Effective pipe routing is a skill honed through experience and knowledge of best practices. Practical piping design and layout courses, often incorporating 3D modeling exercises, can significantly accelerate learning and help designers create layouts that are safe, functional, and economical, all while adhering to code principles like those in ASME B31.3.

Related Posts

Key Responsibilities of a Piping Engineer 🏗️

December 19, 2025

Ensuring Integrity in Process Piping: Lessons from ASME B31.3

December 18, 2025

Future Trends in Piping Engineering

December 14, 2025