Introduction to Pipe Stress Analysis: Why It’s Critical for Plant Integrity ⚖️

0 comments

Introduction to Pipe Stress Analysis: Why It’s Critical for Plant Integrity ⚖️

- Introduction: Define pipe stress analysis. Why it's more than just "checking pipes." Its role in ensuring safety, reliability, and regulatory compliance.

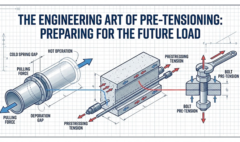

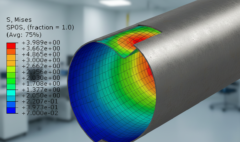

- What is Pipe Stress? Forces and moments acting on the pipe wall, leading to internal stresses (tensile, compressive, shear, bending, torsional).

- Primary Objectives of Pipe Stress Analysis:

- Ensure stresses in the piping system are within allowable limits defined by codes (e.g., ASME B31.3, B31.1).

- Calculate forces and moments on connected equipment nozzles (pumps, turbines, vessels) and keep them within vendor/code allowables.

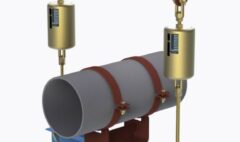

- Calculate loads on pipe supports for their proper design.

- Determine piping displacements and ensure they don't cause interference or issues.

- Address dynamic effects like vibration or seismic events.

- Optimize piping layout and support scheme for cost and safety.

- Types of Loads Acting on Piping Systems (Brief Overview - detailed in another post):

- Sustained Loads: Pressure, weight.

- Expansion Loads: Thermal effects.

- Occasional Loads: Wind, seismic, PSV discharge, water hammer.

- Consequences of Inadequate or No Stress Analysis:

- Catastrophic failures (ruptures, explosions) leading to injuries, fatalities, environmental damage.

- Leaks, leading to loss of containment, production downtime, environmental issues.

- Damage to connected equipment (e.g., pump casing distortion, vessel nozzle cracks).

- Support failures.

- Excessive vibration leading to fatigue failure.

- Regulatory non-compliance and potential legal liabilities.

- Increased maintenance costs and reduced plant lifespan.

- When is Formal Pipe Stress Analysis Required?

- High pressures and/or temperatures.

- Large pipe diameters.

- Connections to sensitive equipment.

- Systems subject to significant dynamic loads.

- Critical or hazardous fluid services.

- ASME B31.3 Para 319.4.1 provides guidance on when formal flexibility analysis is needed. Often, company or project specifications are more stringent.

- The Role of ASME Codes (especially B31.3):

- Provides allowable stress criteria.

- Defines load cases and combinations.

- Specifies methods for calculating stresses (e.g., Stress Intensification Factors - SIFs).

- Gives rules for flexibility and support.

- The Pipe Stress Analysis Process (Simplified Workflow): Model creation -> Load definition -> Analysis -> Results interpretation -> Design modification (if needed) -> Reporting.

- Conclusion & Call to Action: Pipe stress analysis is a critical engineering discipline that underpins the safety and operational integrity of any plant with piping. Foundational courses in pipe stress analysis, covering the principles, methodologies, and the application of ASME B31.3, are essential for engineers who need to perform, review, or understand these vital calculations. This knowledge protects assets, people, and the environment.

Related Posts

Pipe Shell at Moment Support

January 8, 2026

The Constant Spring Hanger: Engineering Magic

January 7, 2026

The Variable Spring Base Support (Spring Can)

January 6, 2026

The Variable Spring Hanger: The Standard Solution

January 5, 2026