Sustained vs. Occasional vs. Expansion Stresses: Understanding Load Cases in Piping (ASME B31.3) 🌡️💨

Sustained vs. Occasional vs. Expansion Stresses: Understanding Load Cases in Piping (ASME B31.3) 🌡️💨

Piping systems are the arteries of any industrial plant, carrying fluids—sometimes hazardous, often at high pressures and temperatures. Ensuring their structural integrity isn’t just about good engineering; it’s about safety, reliability, and environmental protection. A critical aspect of this is pipe stress analysis, which involves evaluating the stresses in a piping system subjected to various loads. The ASME B31.3 Process Piping Code provides the foundational rules for this analysis, categorizing stresses into distinct types based on the loads causing them. Understanding these categories—Sustained, Occasional, and Expansion Stresses—is paramount for any piping engineer or designer.

Why Differentiate Load Cases and Stresses?

Piping systems don’t just sit there; they respond to a multitude of forces. Some forces are constant, others are intermittent, and some arise from the operational conditions themselves. ASME B31.3 recognizes that the material can withstand different levels of stress depending on the nature and duration of the load. This differentiation allows for an optimized and safe design without being overly conservative or, conversely, dangerously under-designed.

- Sustained Loads and Stresses: The Constant Companions

Sustained loads are those that are present throughout the normal operation of the plant. Think of them as the baseline forces the piping system must constantly endure.

- What are they?

- Internal Pressure: The force exerted by the fluid inside the pipe. This creates hoop stress (circumferential) and longitudinal stress.

- Deadweight: The weight of the pipe itself, the fluid it contains, insulation, attached components like valves and fittings, and any permanently installed equipment.

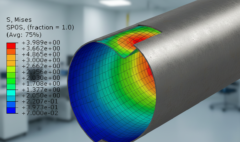

- Impact on Piping:

Sustained loads, particularly weight, cause the pipe to bend and sag between supports. If not properly managed, this can lead to excessive stresses, potentially causing the pipe to yield or even collapse over time. The longitudinal stresses from pressure also contribute to this.

- ASME B31.3 Considerations:

ASME B31.3, Para. 302.3.5, specifies that the sum of longitudinal stresses due to pressure, weight, and other sustained loadings (SL) shall not exceed the basic allowable stress in tension for the material at the operating temperature (Sh).

SL≤Sh

This check ensures the pipe won’t fail under long-term, steady conditions. Proper supporting is key to managing sustained stresses.

- Importance of Learning:

Understanding how to accurately calculate weight loads, model supports, and interpret the stress analysis results for sustained cases is fundamental. Courses in foundational pipe stress analysis will drill deep into these calculations and the application of ASME B31.3 for sustained load cases, ensuring your designs are inherently safe from the ground up.

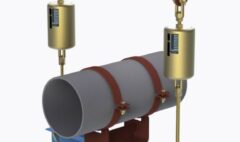

- Occasional Loads and Stresses: The Intermittent Challengers

Occasional loads are, as the name suggests, not always present. They occur due to specific, often short-duration events.

- What are they?

- Wind Loads: Forces exerted by wind on exposed piping.

- Seismic Loads (Earthquake Loads): Forces induced by ground motion during an earthquake.

- Pressure Relief Valve (PRV) Discharge: Thrust forces generated when a PRV opens.

- Water Hammer/Steam Hammer: Forces due to sudden changes in fluid momentum.

- External Impact (e.g., dropped objects, though often mitigated by other means).

- Impact on Piping:

These loads can impose significant, often dynamic, forces on the piping system. The stresses they induce can be much higher than sustained stresses but are tolerated for shorter durations.

- ASME B31.3 Considerations:

ASME B31.3, Para. 302.3.6, allows for a temporary increase in allowable stress for occasional loads. Typically, the sum of longitudinal stresses from all sustained loads plus those from occasional loads may reach 1.33 times Sh. However, this factor can vary based on the specific load and its duration (e.g., test conditions have different allowables). It’s crucial to check the code for the specific condition.

SL(sustained + occasional)≤k⋅Sh

Where ‘k’ is the occasional load factor (commonly 1.33).

- Importance of Learning:

Analyzing occasional loads often requires more advanced techniques, including dynamic analysis for seismic or fluid hammer events. Specialized courses focusing on dynamic analysis and the interpretation of ASME B31.3 for occasional loads are vital for engineers working on projects in seismically active areas or systems prone to hydraulic shock. Understanding these principles prevents catastrophic failures during unforeseen events.

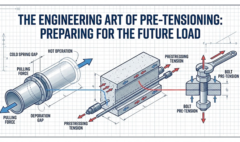

- Expansion Loads and Stresses (Thermal Stresses): The Inevitable Response

Expansion loads arise from the thermal expansion or contraction of the pipe material as it heats up or cools down during operation. If this movement is restrained, it induces stress in the pipe.

- What are they?

- Thermal Expansion/Contraction: Changes in pipe length and volume due to temperature changes from ambient to operating conditions, or between different operating states.

- Imposed Anchor Movements: If connected equipment (like turbines or vessels) thermally grows, it can impose displacements on the connected piping.

- Impact on Piping:

These stresses are typically “self-limiting.” This means that if the pipe yields locally due to thermal stress, the stress is redistributed, and the pipe often doesn’t rupture catastrophically from this alone (unlike pressure-induced failure). However, repeated cycles of thermal expansion and contraction can lead to fatigue failure over time. These stresses also impose forces and moments on connected equipment nozzles and pipe supports.

- ASME B31.3 Considerations:

ASME B31.3, Para. 302.3.5(d), addresses displacement stresses. The calculated displacement stress range (SE) must be less than the allowable displacement stress range (SA).

SE≤SA

The allowable displacement stress range is calculated using:

SA=f⋅(1.25⋅Sc+0.25⋅Sh)

(For older code editions, it could also be SA=f⋅(1.25⋅(Sc+Sh)−SL) or similar formulations, always check the applicable code edition and para. 319.4.4 for cyclic conditions).

Where:

- f = stress range reduction factor for cyclic conditions (1.0 for up to 7000 cycles, reduced for more cycles).

- Sc = basic allowable stress at minimum metal temperature expected during the displacement cycle.

- Sh = basic allowable stress at maximum metal temperature expected during the displacement cycle. This check ensures the pipe can withstand the cyclic nature of thermal loads without fatigue failure within its design life.

- Importance of Learning:

Managing thermal expansion is a core part of pipe stress analysis. This involves designing adequate flexibility into the system using loops, offsets, or expansion joints. Courses on flexibility analysis, stress intensification factors (SIFs), and the application of ASME B31.3 Chapter II Part 5 (Flexibility and Support) are crucial. Understanding these concepts helps protect not only the piping but also sensitive connected equipment from excessive thermal loads.

Load Combinations: The Full Picture

In reality, these loads don’t always act in isolation. Stress analysis software combines these loads into various operating, occasional, and expansion cases to find the worst-case scenarios for the piping system. ASME B31.3 provides guidance on how these loads should be combined and evaluated.

Conclusion: Knowledge is Your Best Defense

A thorough understanding of sustained, occasional, and expansion load cases, and how they are treated under ASME B31.3, is non-negotiable for anyone involved in piping design and analysis. It’s the bedrock upon which safe and reliable piping systems are built. Incorrectly categorizing a load or applying the wrong allowable stress can have severe consequences, from leaks and operational disruptions to catastrophic failures endangering personnel and the environment.

Investing in comprehensive training and continuous learning in pipe stress analysis and ASME code interpretation is not just a career boost; it’s a responsibility. Ensure your knowledge is up-to-date and robust to design piping systems that stand the test of time and temperament.