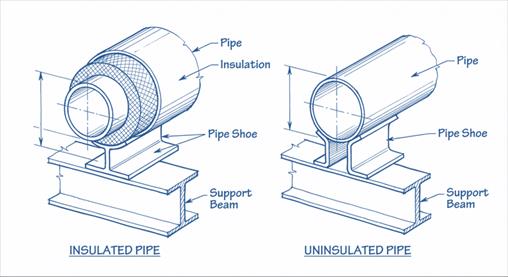

The Pipe Shoe: The Insulated Line’s Best Friend

1. Definition & Function Deep Dive

A pipe shoe (or “pipe slide”) elevates the insulated pipe above the supporting steel. Without a shoe, the insulation would be crushed against the support beam at every resting point, destroying its thermal properties and creating a moisture trap. The shoe allows the pipe to slide axially on the rack while keeping the delicate insulation jacket intact.

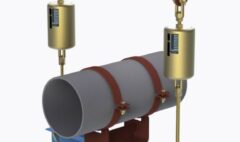

2. Vendor & Fabrication Nuances

- Welded vs. Clamp-On: Welded shoes (T-posts or fabricated plates) are standard for high temperatures. However, welding a shoe onto a pre-heat-treated or exotic alloy pipe can be complex. In these cases, major vendors supply “clamp-on” shoes that use heavy-duty bolts to secure the shoe to the pipe without penetrating the pipe wall.

- Length Matters: The length of the shoe base is critical. The piping stress engineer must calculate total thermal travel. If a pipe is expected to slide 6 inches east when hot, the shoe base must be long enough so it doesn’t slide completely off the support beam and drop the pipe.

3. Troubleshooting & “War Stories”

- The CUI Trap: The interface where a welded shoe meets the pipe is a prime location for Corrosion Under Insulation. If the seal weld isn’t perfect, water gets in and cannot get out. Advanced designs use “stand-off” plates to minimize contact area.

- The Stuck Shoe: If a carbon steel shoe rests on a carbon steel beam in a marine environment, they will eventually rust together. When the pipe tries to expand thermally, the friction is immense, potentially buckling the pipe or tearing the support steel. The solution is using low-friction PTFE (Teflon) slide plates between the shoe and the beam.