The Ultimate Guide to Pipe Supports: Beyond Gravity

Pipe Supports

1. Introduction: The Unsung Heroes of Plant Safety

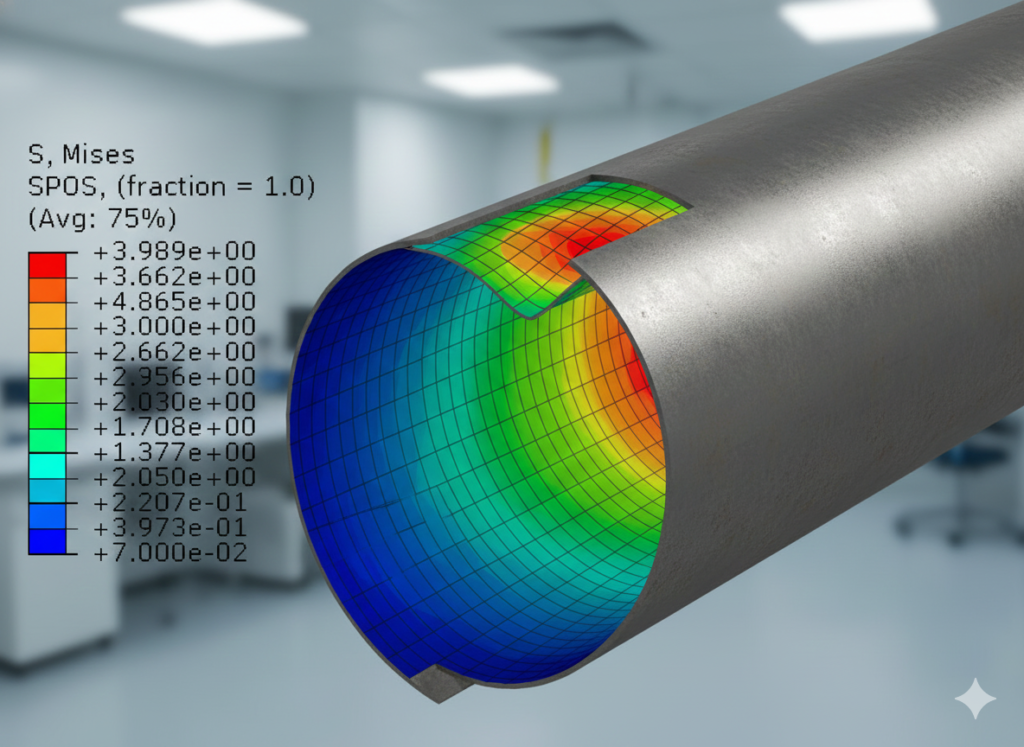

A piping system is more than just tubes transporting fluid; it is a dynamic, breathing entity. It expands with heat, contracts with cold, vibrates with flow, and jolts during pump startups. Pipe supports are not merely “shelves” to hold pipes up against gravity. They are complex structural elements designed to manage energy. Improper support leads to nozzle loads that crack pump casings, sagging lines that pool corrosive condensates, and, in catastrophic scenarios, high-pressure line ruptures. A robust support strategy is the difference between a 30-year plant life and constant emergency maintenance.

2. What is a Pipe Support? (The Engineering Definition)

While the simplest definition is “holding weight,” in piping stress analysis, a support represents a boundary condition. It is a deliberate restriction of degrees of freedom. A support is designed to:

- Sustain Primary Loads: Dead weight of pipe, fluid, insulation, and valves.

- Manage Secondary Loads: Thermal expansion and contraction cycles.

- Resist Occasional Loads: Wind, seismic events, water hammer, and safety valve discharge thrust.

3. Governing Codes & Standards: The Rulebook

It is crucial to distinguish between design codes and fabrication standards.

- ASME B31 Series (B31.1 Power Piping, B31.3 Process Piping): These are system design codes. They tell the piping engineer where supports are needed and what loads they must withstand at what condition to keep pipe stresses within allowable limits.

- MSS SP-58 (Manufacturers Standardization Society): This is the “hardware catalog” standard. It dictates how a support should be fabricated, materials to be used, and load ratings for standard components. It ensures an Anvil Figure 260 bought in Texas is essentially the same as one bought in Dubai.

4. General Selection Criteria: The Stress Analyst’s Job

Selection isn’t guesswork; on critical lines, it’s driven by computerized stress analysis (using software like Caesar II or Auto PIPE).

- Temperature: The primary driver of thermal growth. High-temp lines need room to move (springs, slides); cryogenic lines need insulation blocks to prevent ice formation on the steel support.

- Material Compatibility: You cannot rest a stainless-steel pipe directly on a carbon steel beam in a wet environment due to galvanic corrosion.

- Space Constraints: A crowded pipe rack might not have room for a large spring hanger, forcing alternative designs.

5. Common Materials, Fabrication & Painting

Standard supports are usually A36 or equivalent carbon steel. Fabrication ranges from mass-produced forged components (like clevises) to custom-fabricated heavy structural weldments (like anchors). The critical factor here is Corrosion Under Insulation (CUI). Supports on insulated lines must be painted with high-temp systems suited for the operating range, as moisture trapped between the support and the insulation is a leading cause of pipe failure.

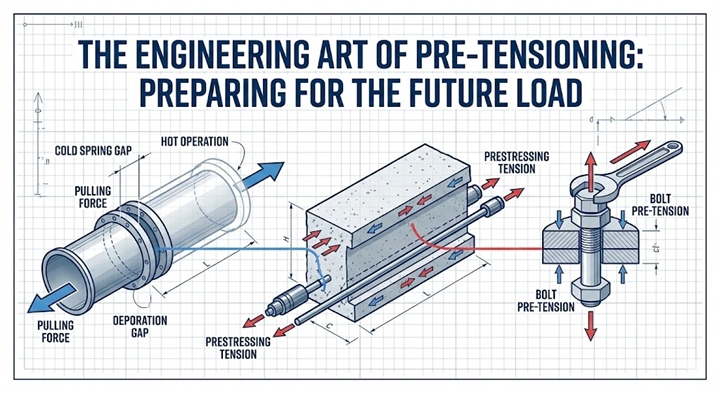

6. Installation & Maintenance Principles: The Reality Gap

The best design fails if installed poorly[MA1] . A common issue is supporting steel being erected slightly off-elevation, forcing the pipe fitter to “pull” the pipe down to meet the support, introducing pre-load stresses before the plant even turns on.

- Maintenance Tip: Walk down high-temp lines when the plant is cold (shutdown) and when it is hot (operating). Did the pipe lift off its supports when hot? Is it bottoming out a spring hanger? These are red flags.

7. Pipe supports in asset management programs

Integrating pipe supports into a comprehensive asset management program is critical because these components act as the essential, often overlooked, structural foundation for piping integrity and process safety. Far from being passive hardware that can be installed and forgotten, pipe supports—including hangers, snubbers, and anchors—are dynamic assets susceptible to time-dependent degradation mechanisms such as corrosion, spring fatigue, and mechanical wear due to thermal cycling and vibration. Neglecting their condition disrupts the engineered stress balance of the entire system, transferring unintended loads directly onto the piping pressure boundary and sensitive connected equipment like pumps and vessels. Consequently, a failure to include supports in risk-based maintenance strategies transforms minor hardware degradation into major operational risks, potentially leading to catastrophic containment breaches, costly unscheduled downtime, and compromised life-cycle value of the facility.

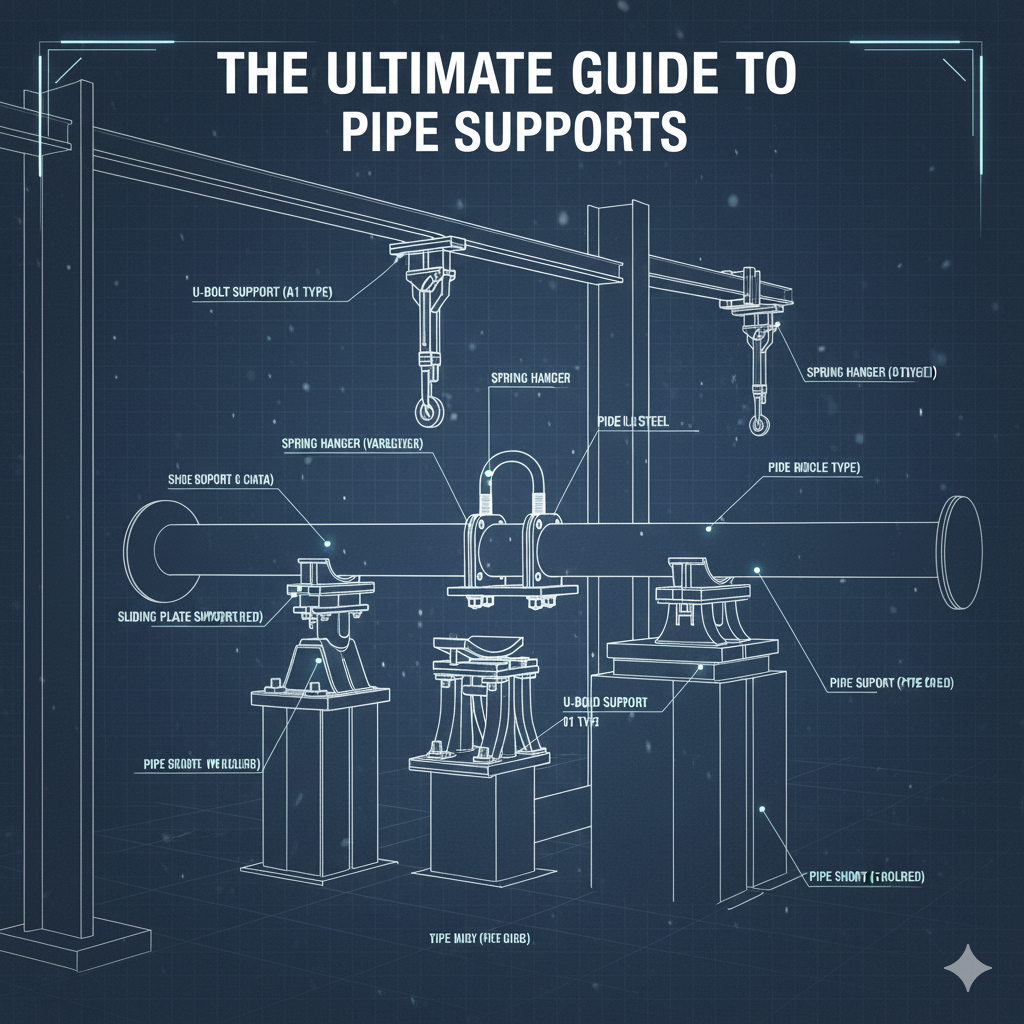

8. Pipe supports categories

Pipe supports can be categorized based on their primary function within a piping system. These categories are not mutually exclusive, as many supports perform multiple functions simultaneously.

8.1 Load-Bearing Supports (Weight Support)

The most fundamental function of a pipe support is to carry the dead weight of the piping system, including the pipe itself, fittings, valves, insulation, and the fluid it contains. These supports prevent the pipe from sagging, which could lead to stress concentration, leakage, or damage to connected equipment.

Common types include:

- Clevis Hangers: Simple hangers that support the pipe from above.

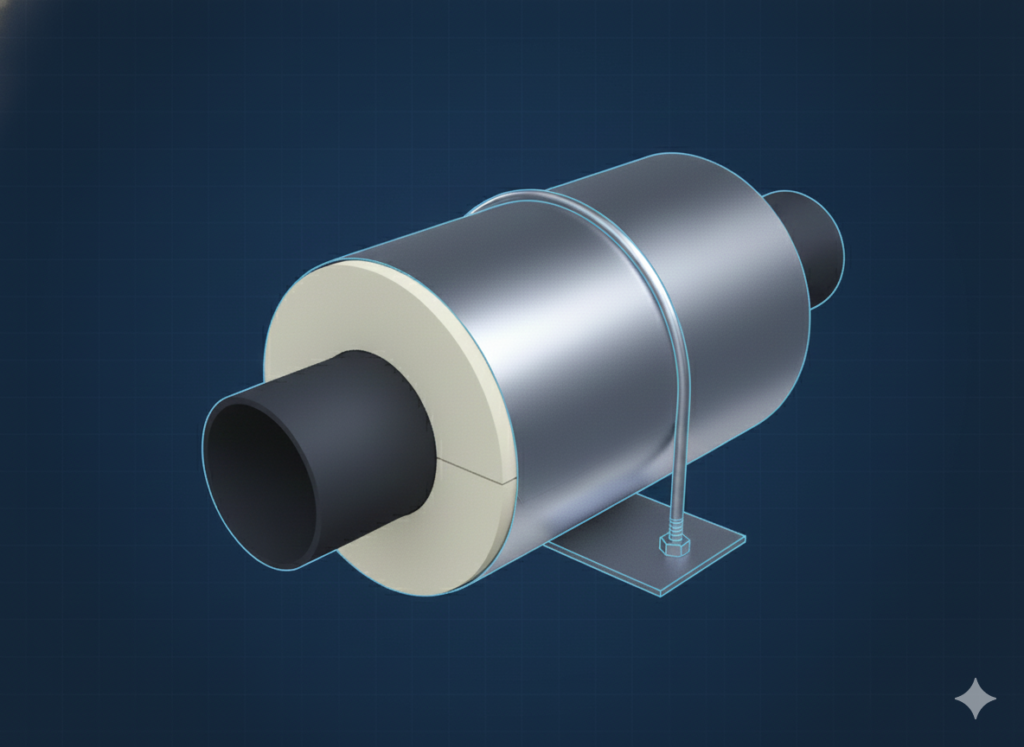

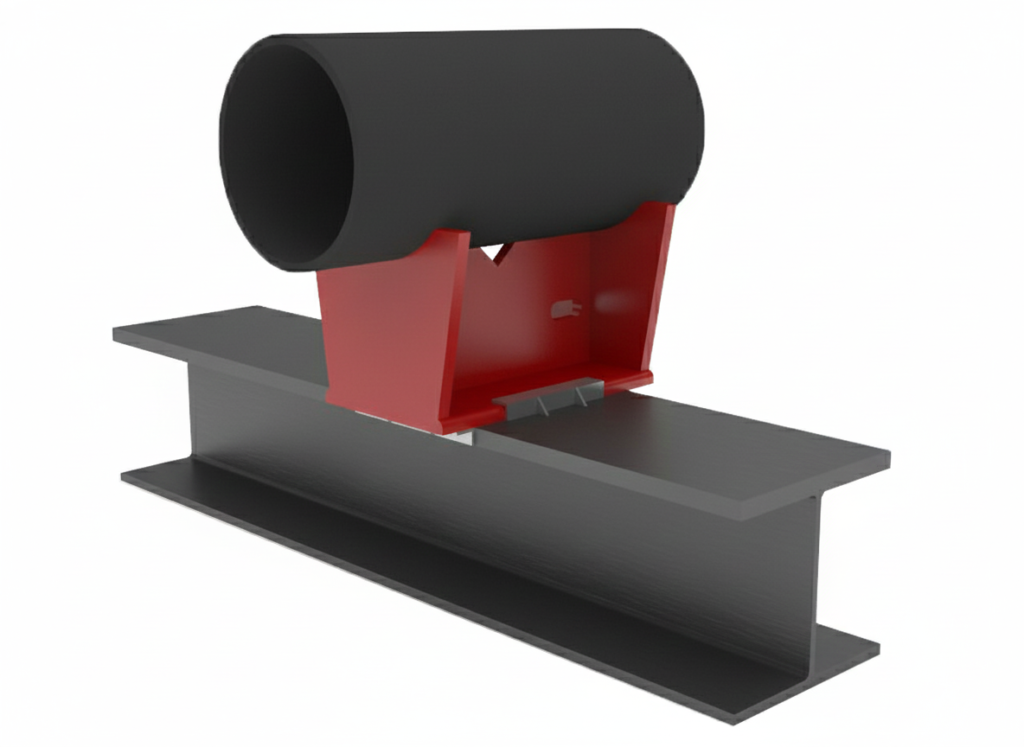

- Pipe Saddles & Shoes: Supports that cradle the pipe from below, often used for larger pipes or to protect insulation.

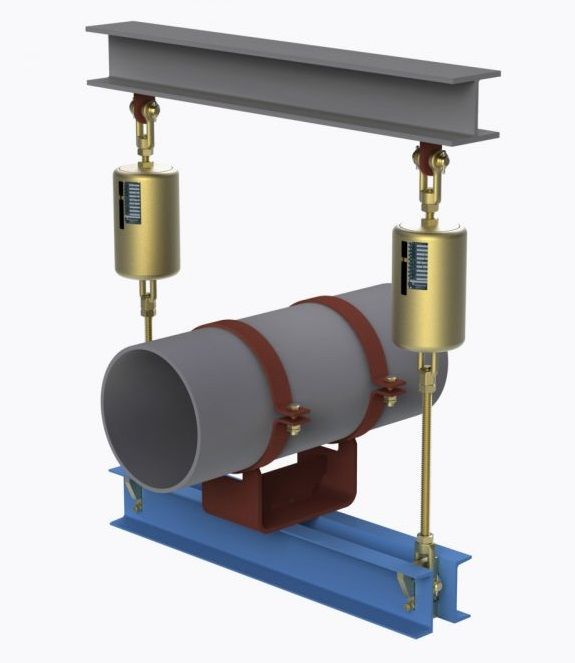

- Spring Hangers (Variable & Constant): Used to support heavy loads while accommodating vertical movement due to thermal expansion.

8.2 Restraint and Guiding Supports (Movement Control)

These supports are designed to control or restrict the movement of the pipe caused by thermal expansion and contraction, fluid forces, or other external loads. Their primary goal is to ensure the pipe moves in a predictable and safe manner, preventing damage to the pipe, supports, and connected equipment.

Common types include:

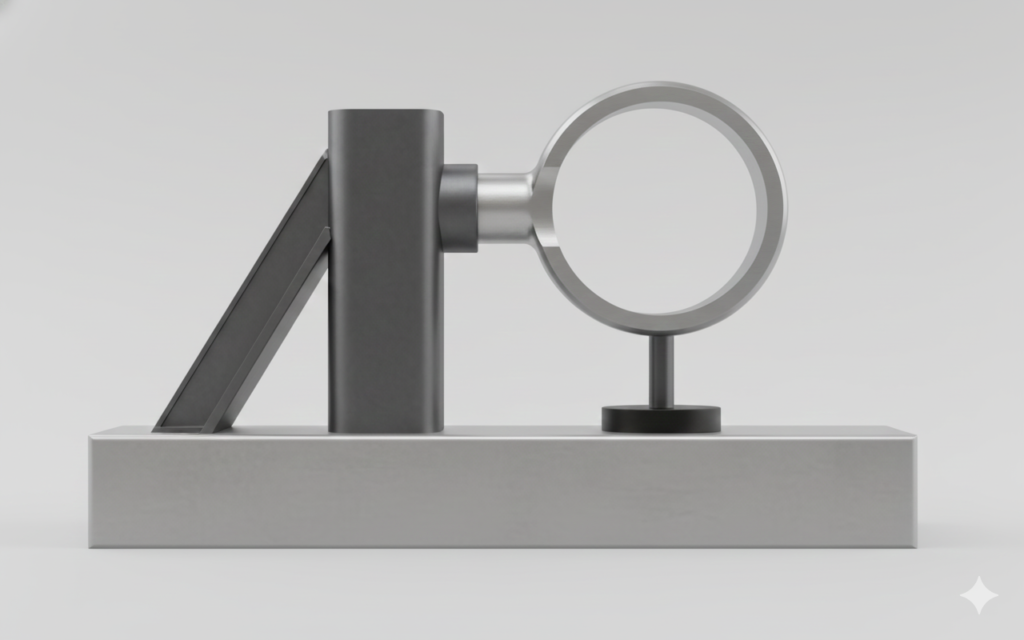

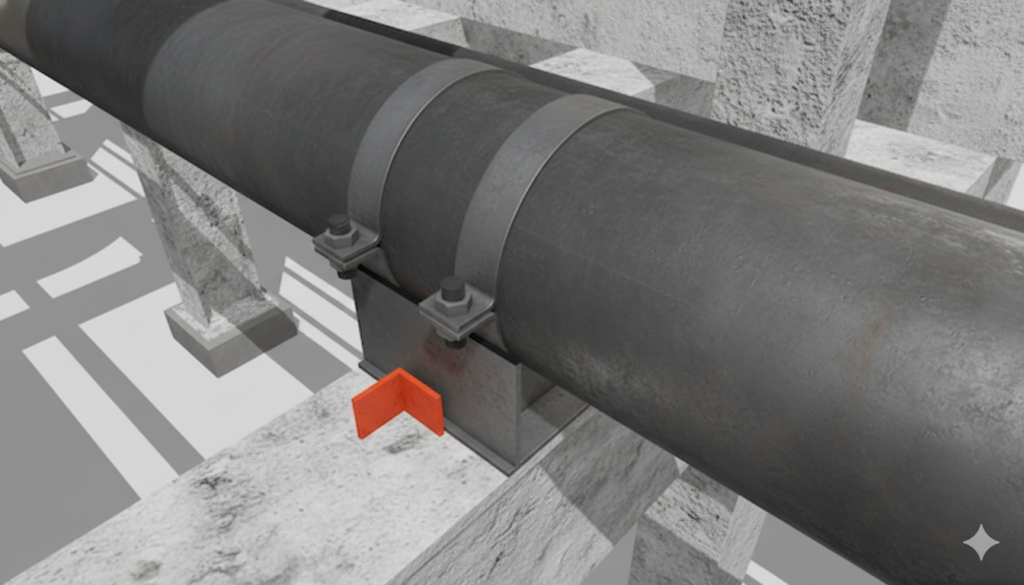

- Pipe Guides: Allow movement along the axis of the pipe but restrict lateral (sideways) or vertical movement.

- Anchors: Rigid supports that prevent movement in all three directions (axial, lateral, and vertical). They are typically placed at critical points to fix the pipe’s position.

- Limit Stops: Allow a specific amount of movement in one or more directions before acting as a restraint.

- Slide Plates: Low-friction plates placed between the pipe shoe and the supporting structure to facilitate axial movement and reduce friction forces.

8.3 Vibration and Shock Control Supports (Energy Absorption)

These supports are designed to dampen vibrations caused by fluid flow, pump operation, or other dynamic forces. They also absorb sudden shocks from events like water hammer or seismic activity, protecting the piping system from fatigue failure and acute damage.

Common types include:

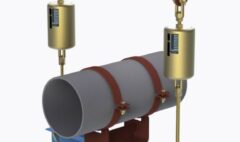

- Snubbers (Hydraulic & Mechanical): Devices that allow slow thermal movement but lock up during sudden shock loads to restrain the pipe.

- Sway Braces: Used to limit vibration and swaying of the pipe, acting like a spring to oppose movement.

- Resilient Supports: Supports incorporating elastomeric materials or springs to isolate the pipe from structure-borne vibrations and dampen noise.

[MA1]Installation mistakes of pipe support