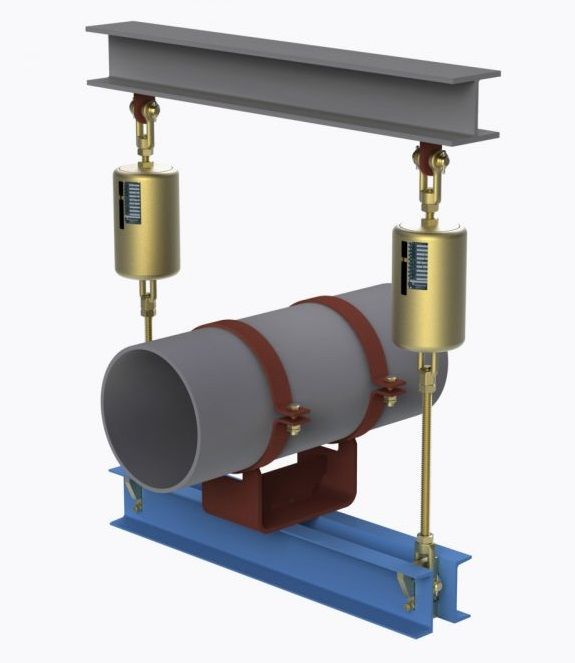

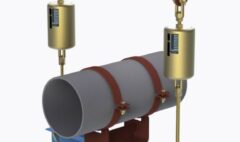

The Variable Spring Base Support (Spring Can)

Pipe Supports

1. Definition & Function Deep Dive

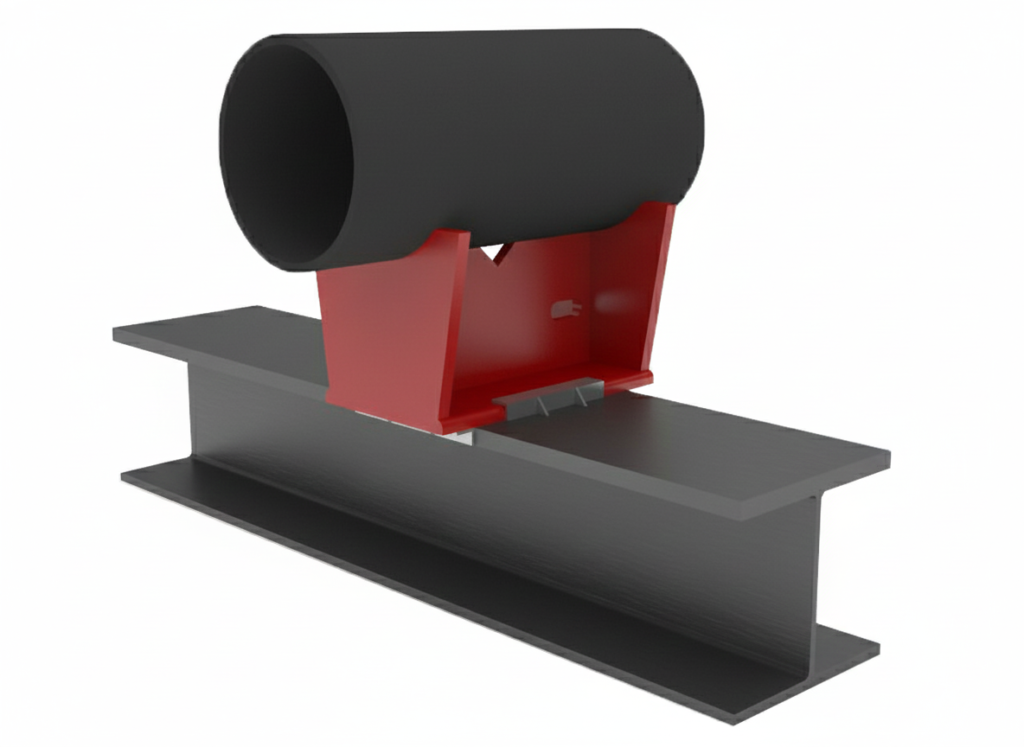

Functionally identical to the variable spring hanger (Post 9), but packaged for resting applications. It’s a spring stuck in a can, placed under the pipe.

2. Application Nuances

These are used when pipes are routed close to the floor or low structural steel, where hanging them from above isn’t practical. They are often placed directly under a pipe shoe, or under the trunnion of a vertical pipe elbow.

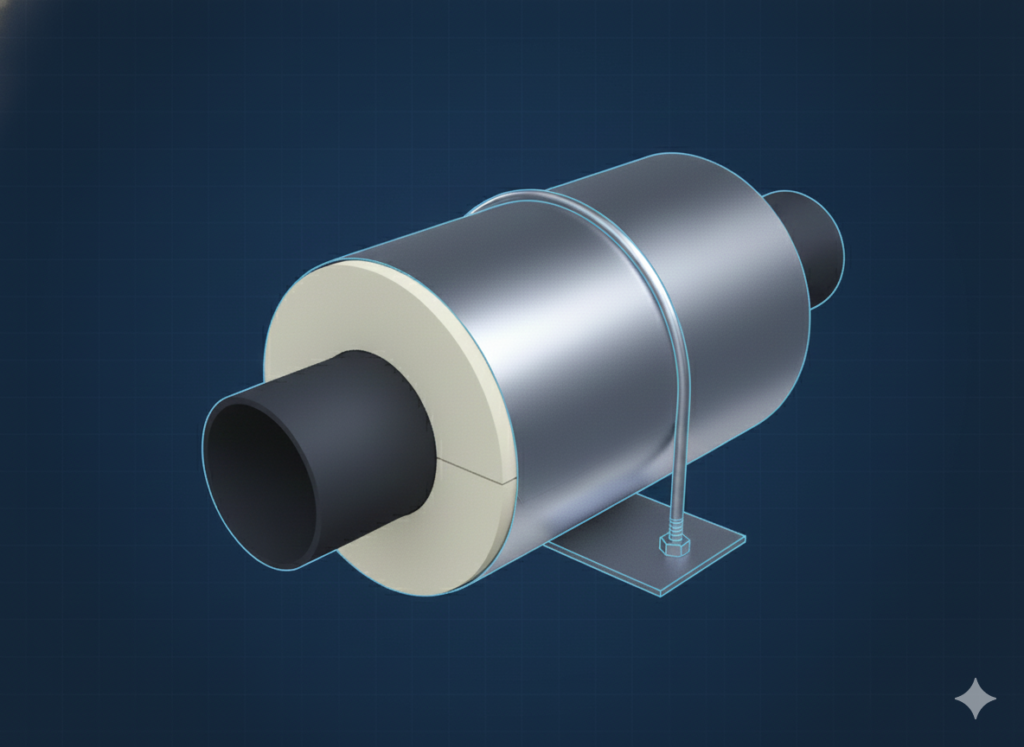

3. Troubleshooting: Stability and Environment

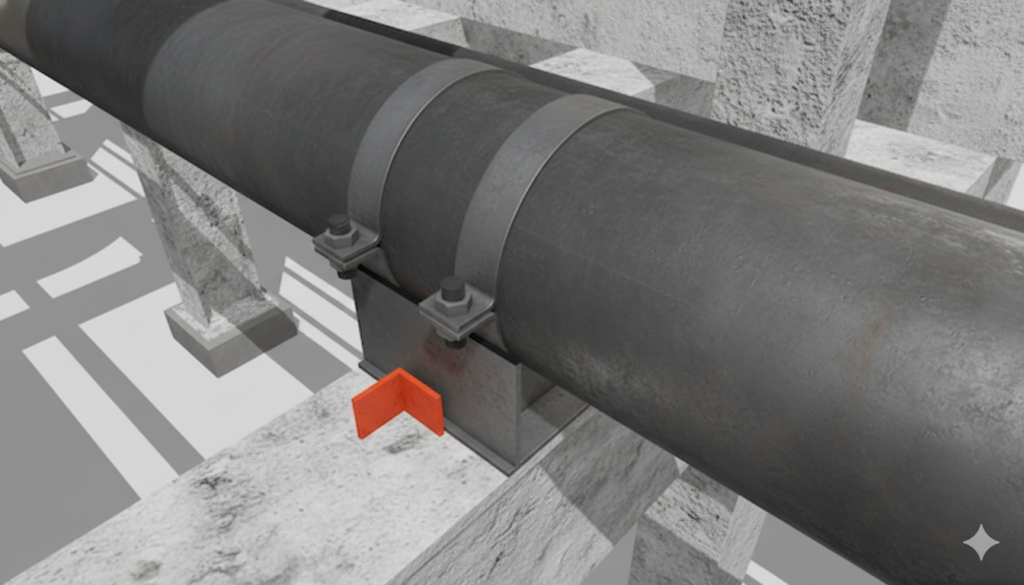

- The “Wobble” Factor: Because the pipe is resting on a spring mechanism from below, lateral stability can be an issue. Base springs are almost always paired with nearby lateral guides (Post 7) to prevent the pipe from “falling off” the spring can during seismic events or water hammering.

- Environmental Attack: Because they sit low to the ground or on concrete piers, base springs are highly susceptible to standing water, wash-downs, and debris accumulation. The moving load flange can get jammed by grit, or the casing can corrode rapidly if not specified with appropriate marine-grade coatings or stainless-steel housings.

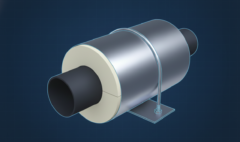

4. Vendor Spotlight: Piping Technology & Products (PT&P)

Leading vendors, such as Piping Technology & Products (PT&P), approach spring design with specific features to address the challenges outlined above.

4.1 Enhanced Environmental Protection:

For base supports in corrosive or marine environments, standard paint (e.g., carbon steel with red oxide primer) is insufficient. PT&P, for example, often offers:

4.1.1 Hot-Dip Galvanizing: For outdoor or mild chemical exposure.

4.1.2 Specialty Coatings: Such as epoxy or three-coat systems for severe conditions, or an all-stainless steel housing option for environments with high wash-down frequency or salt spray.

4.2 Load Adjustment Mechanism:

Base supports, like hangers, require field adjustment. Vendors provide a load adjustment bolt, often accessible from the top, to set the spring to the correct “cold” installed height. A key vendor practice is to provide clear, stamped load-travel plates or a physical indicator that shows the spring’s position in relation to its total travel.

4.3 Stability and Friction:

To minimize the “Wobble” factor and ensure the pipe slides correctly across the can’s upper flange, vendor specifications often include:

- PTFE/Neoprene Pads:

A low-friction bearing surface is installed directly on the top load flange of the spring can to ensure axial movement is smooth and to reduce wear between the pipe shoe and the support itself.

- Pre-Compressed Design:

Some vendor models are shipped pre-compressed, which provides greater lateral stiffness than an open spring design, improving stability against side-loads.

4.4 Piping Technology & Products (PT&P) offers the following design features for variable spring base supports to address corrosive or marine environments:

4.4.1 Hot-Dip Galvanizing:

This is offered for base supports in outdoor or mild chemical exposure conditions.

4.4.2 Specialty Coatings:

These include options such as epoxy or three-coat systems for severe corrosive conditions.

4.4.3 All-Stainless-Steel Housing:

This option is available for environments with high wash-down frequency or significant salt spray (marine environments).