Valve Selection and Specification: A Critical Aspect of Piping Design ⚙️

0 comments

Valve Selection and Specification: A Critical Aspect of Piping Design ⚙️

1. Introduction

Why valves are more than just “taps.” Their crucial roles in controlling flow, isolating equipment, and ensuring safety. The cost and impact of correct vs. incorrect valve selection.

2. Functions of Valves in Piping Systems

- Isolation (On/Off): For maintenance, shutdown (Gate, Ball, Plug, Butterfly).

- Regulation (Throttling): Controlling flow rate or pressure (Globe, Needle, some Ball/Butterfly, Control Valves).

- Non-Return (Check): Preventing reverse flow (Swing Check, Lift Check, Ball Check).

- Pressure Relief: Protecting against overpressure (Pressure Relief Valves, Safety Valves).

- Special Purposes: Diverting flow, sampling, etc.

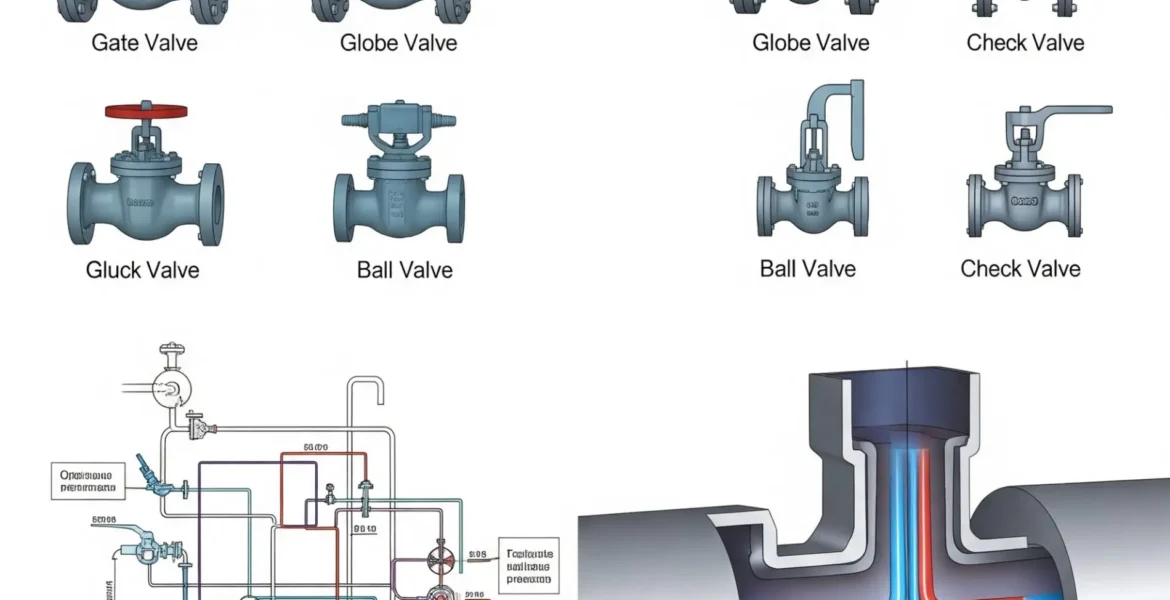

3. Common Types of Valves: Construction, Operation, Pros & Cons

- Gate Valves: Good for isolation, minimal pressure drop when fully open, poor for throttling.

- Globe Valves: Good for throttling and tight shut-off, higher pressure drop.

- Ball Valves: Quick quarter-turn operation, good shut-off, can be used for throttling (with characterized balls).

- Plug Valves: Similar to ball valves, robust, good for slurries.

- Butterfly Valves: Quarter-turn, lightweight, compact, lower cost for large sizes, can be used for isolation and throttling.

- Check Valves (Swing, Lift, Tilting Disc, Piston): Automatic operation to prevent backflow.

- Control Valves: Automated valves with actuators and positioners for precise process control. Body type often globe, ball, or butterfly.

4. Key Valve Selection Criteria

- Fluid Properties: Corrosiveness, viscosity, solids content, toxicity, flammability.

- Operating Conditions: Pressure, temperature (design and operating).

- Flow Rate & Control Requirements: On/Off, throttling, tight shut-off, Cv (flow coefficient).

- Line Size and Connection Type: Flanged, welded, threaded.

- Material Compatibility: Body, trim, seals/packing with the fluid and environment.

- Leakage Class Requirements.

- Industry Standards and Specifications.

- Cost, Availability, and Maintainability.

5. Valve Standards and Codes

- ASME B16.34: Valves – Flanged, Threaded, and Welding End (pressure-temperature ratings, dimensions).

- ASME B16.10: Face-to-Face and End-to-End Dimensions of Valves.

- ASME B16.5 / B16.47: Pipe Flanges and Flanged Fittings (for valve end connections).

- API 6D/6DSS: Specification for Pipeline and Piping Valves.

- API 600: Steel Gate Valves—Flanged and Butt-welding Ends, Bolted Bonnets.

- API 602: Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries.

- API2 598: Valve Inspection and Testing.

- Materials often specified per ASTM standards, design of valve bodies (if pressure-containing) links to principles in ASME Section VIII and ASME B31.3.

6. Creating Valve Data Sheets (VDS)

- Compiling all necessary information for procurement.

7. Common Valve Problems and Troubleshooting

- Leaks (stem, seat, body), sticking, incorrect operation.

8. Conclusion & Call to Action

- Valve selection is a complex process requiring careful consideration of numerous factors. Making the right choice is critical for plant safety, efficiency, and reliability. Specialized courses on valve technology, selection, application, and relevant API/ASME standards provide engineers with the expertise to specify the optimal valves for any given service, preventing costly mistakes and operational issues.

Related Posts

Key Responsibilities of a Piping Engineer 🏗️

December 19, 2025

Ensuring Integrity in Process Piping: Lessons from ASME B31.3

December 18, 2025

Future Trends in Piping Engineering

December 14, 2025