Mastering P&IDs: The Language of Piping Engineers 🗺️

Introduction:

What is a Piping and Instrumentation Diagram (P&ID)? Analogy to a roadmap or blueprint for a process plant. Its central role in communication.

Purpose and Importance of P&IDs:

- Depicting process flow, equipment, instrumentation, and control systems.

- Basis for design, construction, operation, maintenance, and safety analysis.

- Key document for HAZOP studies and safety reviews.

Key Elements and Symbols on a P&ID (with examples):

- Equipment: Vessels, pumps, compressors, heat exchangers, columns, reactors (ISA S5.1 symbols).

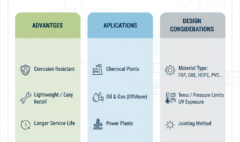

- Piping: Main process lines, utility lines, line numbering conventions, material and size indications, insulation, tracing.

- Valves: Types (gate, globe, ball, check, butterfly, control valves, PSVs), actuation, fail positions (symbols based on ISA S5.1 or company standards).

- Instrumentation: Measurement devices (flow, pressure, temperature, level), control loops, interlocks, symbols (bubbles, lines). Reference to ISA S5.1 for instrumentation symbols.

- Fittings and Ancillaries: Flanges, reducers, spectacle blinds, steam traps, strainers.

- Notes and Legends: Critical information, abbreviations.

How P&IDs Drive Plant Lifecycle Activities:

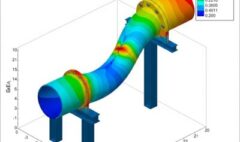

- Design: Basis for plot plans, equipment layout, piping design, material take-offs.

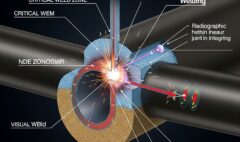

- Construction: Guide for installation and verification.

- Operation: Understanding process control, startup, shutdown, troubleshooting.

- Safety: Essential for Hazard and Operability (HAZOP) studies, identifying safety critical devices.

Reading and Interpreting Complex P&IDs:

Tips and techniques, common pitfalls, importance of consistency and clarity. Connection to Line Lists and Equipment Lists.

ASME References (Indirect):

While P&IDs themselves aren’t directly an ASME code document, the components they depict (e.g., pressure vessels, piping, PSVs) are designed and fabricated according to ASME codes (e.g., ASME Section VIII for vessels, ASME B31.3 for piping, ASME Section I for power boilers which would influence PSV sizing depicted on P&IDs). P&IDs specify design pressures/temperatures that link to these codes.

Conclusion & Call to Action:

P&IDs are the universal language of process plants. Proficiency in reading and developing them is non-negotiable. Specialized courses on P&ID development and interpretation, including understanding symbology and interconnections, are crucial for anyone in piping, process, or plant engineering.