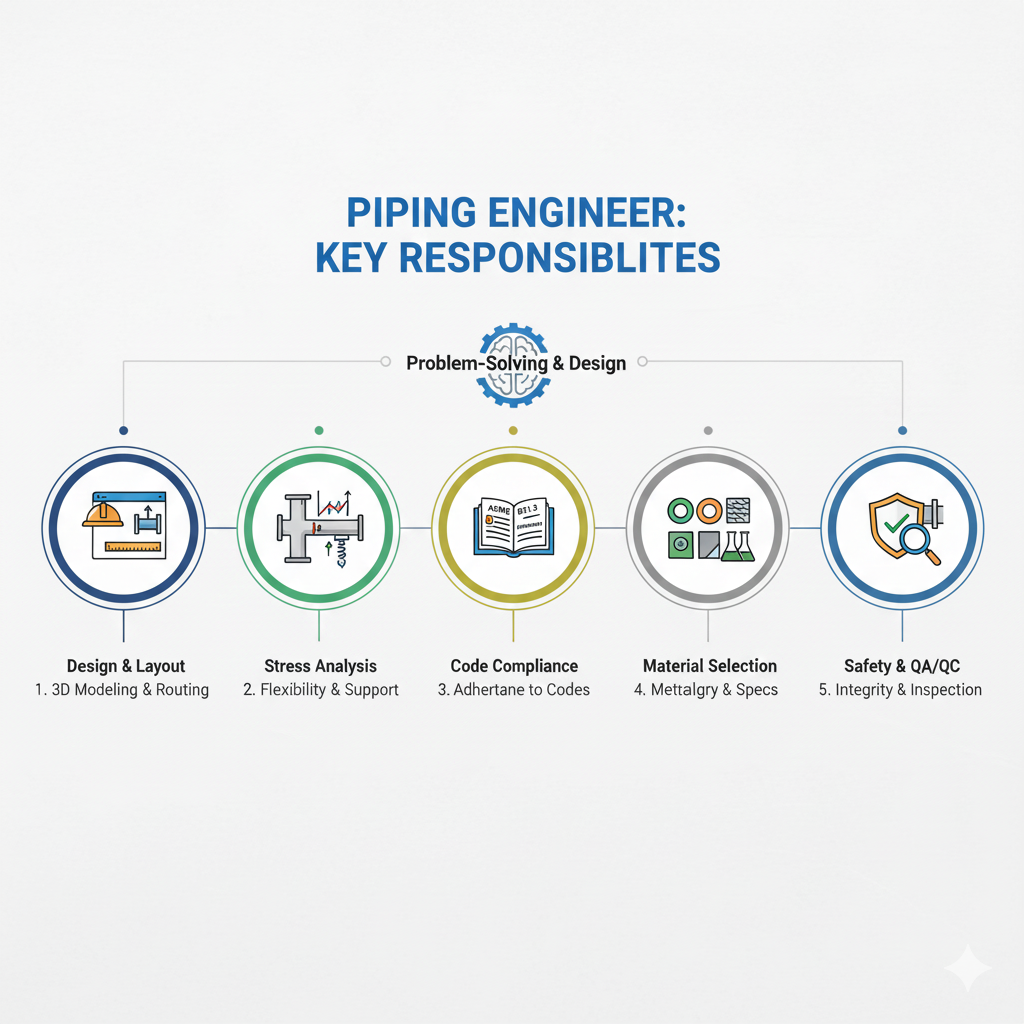

Key Responsibilities of a Piping Engineer 🏗️

Key Responsibilities of a Piping Engineer 🏗️

Key Responsibilities of a Piping Engineer 🏗️

1. Design and Layout, Material Selection, Stress Analysis, Support Design

This area represents the core technical design activities of a piping engineer.

1.1 Design and Layout:

- Piping and Instrumentation Diagram (P&ID) Development: Collaborating with process engineers to develop and refine P&IDs, which are the schematic blueprints for the entire plant.

- Plot Plan and Equipment Layout: Developing or providing critical input on the overall plant layout, ensuring optimal spacing for safety, accessibility, and constructability.

- 3D Modeling: Creating intelligent 3D models of the piping systems using software like PDMS, E3D, S3D, or AutoCAD Plant 3D. This includes routing pipes to connect equipment nozzles while avoiding clashes with other disciplines (structural steel, electrical cable trays, etc.).

- Piping General Arrangement (GA) Drawings: Generating 2D drawings from the 3D model that show the pipe routing in plan and elevation views.

- Isometric Drawings: Creating detailed, dimensioned drawings for individual pipe spools that are used for fabrication and installation in the field.

1.2 Material Selection:

- Piping Material Specification (PMS): Developing the PMS for a project, which dictates the appropriate materials (pipe, fittings, flanges, valves, bolts, gaskets) for different fluid services based on pressure, temperature, corrosivity, and fluid type.

- Corrosion Studies: Evaluating the potential for corrosion and selecting materials or specifying corrosion allowances and coatings to ensure the long-term integrity of the system.

- Cost-Benefit Analysis: Balancing the technical requirements of materials with their cost and availability to provide a safe and economical solution.

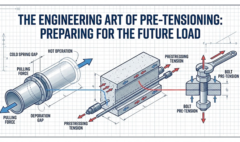

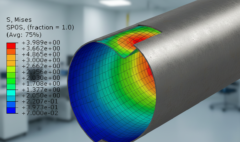

1.3 Stress Analysis:

- Flexibility Analysis: Performing calculations (often using software like CAESAR II or AutoPIPE) to ensure the piping system is flexible enough to absorb thermal expansion and contraction without overstressing the pipe or connected equipment.

- Load Calculations: Analyzing stresses from sustained loads (weight, pressure) and occasional loads (wind, seismic activity, water hammer).

- Nozzle Load Checks: Ensuring the forces and moments exerted by the pipes on the nozzles of sensitive equipment (like pumps, turbines, and vessels) are within the manufacturer’s allowable limits.

- Dynamic Analysis: When required, performing analysis for vibration, slug flow, or pressure relief events to prevent fatigue failure.

1.4 Support Design:

- Support Selection: Choosing the appropriate type of pipe support (e.g., rests, guides, anchors, spring hangers, snubbers) based on the loads and required movement from the stress analysis results.

- Support Location: Specifying the precise location of each support in the 3D model and on isometric drawings.

- Standard and Special Supports: Designing custom supports for unique or heavily loaded situations where standard components are insufficient.

2. Code Compliance (ASME B31 suite, API, etc.)

Ensuring the design is safe and meets all legal and technical requirements is a fundamental responsibility.

- Code Interpretation: Possessing a deep understanding of the relevant codes and standards, primarily the ASME B31 suite (e.g., B31.3 for Process Piping, B31.1 for Power Piping) and industry-specific standards like those from the American Petroleum Institute (API).

- Design Verification: Ensuring all calculations for wall thickness, component ratings, and stress levels strictly adhere to the formulas and allowable limits set forth in the governing code.

- Documentation: Maintaining clear records and documentation that demonstrate code compliance for review by clients, regulatory bodies, and third-party inspectors.

- Staying Current: Keeping up-to-date with the latest revisions and addenda to codes and standards, as they are periodically updated.

3. Safety Reviews (HAZOP, SIL)

The piping engineer plays a critical role in formal safety assessments.

3.1. HAZOP (Hazard and Operability Study):

- Active Participation: Acting as a core team member in HAZOP meetings, representing the piping and layout discipline.

- Providing Information: Using their detailed knowledge of the P&IDs and plant layout to explain how the system is intended to operate.

- Assessing Deviations: Helping to identify potential hazards that could arise from deviations in process parameters (e.g., “no flow,” “high pressure”) and assessing their consequences from a mechanical integrity standpoint (e.g., risk of rupture, leak).

- Action Resolution: Taking ownership of action items that require a design change to mitigate an identified hazard, such as rerouting a pipe, changing a material specification, or adding a bleed valve.

3.2. SIL (Safety Integrity Level) Assessment:

- Input on Safety Instrumented Functions (SIFs): Providing input on the physical design aspects of safety loops, such as the location of sensors, valves, and the integrity of the associated piping, which can impact the overall reliability of the safety function.

4. Interface with other Disciplines

Piping is often called the "central" discipline because it connects to almost every other part of the project.

- Civil/Structural: Providing the locations and loads of all pipe supports so the structural team can design the steel racks and foundations. In turn, receiving the steel and foundation models to ensure pipes do not clash.

- Mechanical (Equipment): Obtaining detailed drawings and nozzle load limits for all equipment (vessels, pumps, heat exchangers) to ensure a proper mechanical and stress-compliant connection.

- Electrical: Coordinating pipe routing to avoid clashes with cable trays, switchgear, and lighting. Ensuring adequate clearance is maintained for safety and maintenance.

- Instrumentation: Providing space and proper orientation for instruments in the piping layout (e.g., control valves, flow meters, pressure gauges). Ensuring straight pipe runs and tap point locations meet instrument requirements.

- Process: Working continuously with process engineers to ensure the piping design accurately reflects the process requirements as defined on the P&IDs.

5. Procurement Support, Construction Support, Commissioning

The engineer's responsibility extends beyond the design phase into the execution of the project.

5.1. Procurement Support:

- Material Take-Offs (MTOs): Generating accurate lists of all piping components required for the project.

- Technical Bid Evaluation: Reviewing bids from suppliers to ensure the components they offer meet the technical requirements of the project specifications and standards.

- Vendor Document Review: Checking technical drawings and documents from manufacturers (e.g., valve drawings, special fitting designs) to approve them for fabrication.

5.2. Construction Support:

- Field Queries: Responding to technical questions and resolving problems that arise from the construction team in the field (e.g., clashes not found in the model, material discrepancies).

- Design Change Management: Issuing revised drawings and instructions to address necessary changes in the field while maintaining design integrity.

- As-Built Drawings: Assisting in the process of updating the original design drawings to reflect the final, as-installed configuration.

5.3. Commissioning:

- System Walkdowns: Physically inspecting the installed piping systems to ensure they have been built according to the design drawings and specifications before startup.

- Testing Support: Providing technical guidance during system testing, such as hydrotesting or pneumatic testing, and helping to troubleshoot any leaks or failures.

- Startup Assistance: Being on-site during the initial plant startup to address any immediate piping-related issues that may arise.

6. Lifecycle of a Piping System:

- Conceptualization & Feasibility.

- Front-End Engineering Design (FEED).

- Detailed Design & Analysis.

- Procurement & Fabrication.

- Construction & Installation.

- Testing & Commissioning.

- Operation & Maintenance.

- Decommissioning.

7. Importance of Codes and Standards:

Focus on ASME B31.3 (Process Piping) as a cornerstone. Brief mention of others like B31.1(Power Piping), B31.4 (Pipeline Transportation Systems for Liquids and Slurries), B31.8 (Gas Transmission and Distribution Piping Systems).1 Why standards ensure safety, reliability, interoperability.

8. Future Trends in Piping Engineering:

Digitization (3D modeling, Digital Twins), modular construction, advanced materials, sustainability, AI in design and maintenance.

9. Conclusion & Call to Action:

Reinforce the vast opportunities and critical importance of the field. Emphasize that foundational courses in piping engineering provide the necessary breadth and depth to excel in this diverse and vital discipline, covering essential principles and code awareness.