Pipe Shell at Moment Support

1. Introduction

A moment anchor is designed to stop tremendous rotational forces (torque) and linear thrust. If you weld the structural steel of the anchor directly to the relatively thin wall of a standard pipe (the “pipe shell”), the localized stress concentration will almost certainly cause the pipe wall to yield, buckle, tear, or crack.

You must reinforce the pipe shell to distribute these massive loads over a larger surface area, reducing the local stress to acceptable levels.

Here are the primary methods used to protect the pipe shell at a moment anchor location, ranked roughly from common to extreme duty.

2. Reinforcing Pads (Re-pads or Wear Pads)

This is the most common method for standard applications. A reinforcing pad is a steel plate, usually rolled to the same curvature as the pipe outside diameter, that is welded to the pipe shell at the anchor location. The structural steel of the anchor is then welded to this pad, not the pipe itself.

- How it works: The pad acts as a stress distributor. It takes the concentrated point-load or torque from the anchor attachment and spreads it over a much wider area of the underlying pipe wall.

- Material & Thickness: The pad material generally must match the base pipe material to prevent galvanic corrosion and ensure similar thermal expansion properties.1 The thickness is typically equal to or slightly greater than the nominal wall thickness of the pipe.

- The “Weep Hole” Requirement: When welding a full encirclement or large partial pad to a pipe, a small vent hole (weep hole) must be drilled in the pad before the final sealing weld is made.

- Fabrication Reason: Heated air trapped between the pad and pipe will expand and “blow out” the final weld if not vented.

- Operational Reason: It acts as a tell-tale. If the carrier pipe develops a leak under the pad, product will drip from the weep hole, alerting operators. Without the hole, the leak could pressurize the space between the pipe and pad, causing a catastrophic blowout of the pad.

3. Heavy Wall Pipe Spools (Stubs)

For higher pressure systems, higher temperatures, or very large anchor loads where a re-pad is insufficient, the best approach is to increase the pipe wall thickness itself.

- How it works: Instead of adding a patch on top, the piping designer specifies that a short section of the piping system at the anchor location be fabricated from a much heavier schedule pipe. For example, in a long run of 12″ Schedule 40 pipe, a 3-foot section at the anchor point might be replaced with 12″ Schedule 120 or Schedule 160 pipe.

- Benefits: This provides a robust, integral pipe wall capable of handling high local stresses without the fabrication complexities of a sandwich structure (pad + pipe). It eliminates concerns about corrosion between a pad and the pipe.

4. Full Encirclement and “Wraparound” Designs

Because a moment anchor deals with torque (rotation), simply welding a lug to the top or side of the pipe is rarely adequate, even with a pad. The force needs to be grabbed around the circumference.

- Stanchions with Saddle Wraps: The structural attachment usually isn’t just a plate; it’s often a large diameter pipe stanchion or a heavy structural shape that is coped (cut to curve) to fit the pipe. This attachment is usually welded to a re-pad that wraps 180 degrees or a full 360 degrees around the pipe to distribute rotational forces evenly.

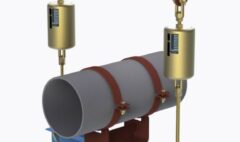

- Trunnions (Dummy Legs): A common design for heavy anchors involves welding “trunnions”—short sections of pipe closed with end caps—perpendicular to the main process pipe on opposite sides (at 3 and 9 o’clock positions). The structural steel anchor then clamps or welds to these trunnions. This is excellent for managing torque, but the intersection where the trunnion welds to the process pipe is a high-stress point that often requires a reinforcing pad itself (a “donut” repad).

5. Integral Forged Fittings (Extreme Duty)

In extremely critical applications, high-pressure steam, or nuclear piping, welding anything to the pipe wall in a high-stress zone might be prohibited due to heat-affected zone (HAZ) concerns.

- How it works: Specialty manufacturers can create a single, forged component that includes the pipe flow path and heavily reinforced, integral anchoring lugs forged directly into the metal body. There are no attachment welds at the highest stress points. These are very expensive and have long lead times.

Summary Table

| Protection Method | Typical Application | Pros | Cons |

| Reinforcing Pad | Standard process piping, moderate loads. | Cost-effective, easy to fabricate in field or shop. | Requires weep hole; potential for corrosion under pad if weld fails. |

| Heavy Wall Spool | High pressure/temp, heavy loads. | Clean stress flow, robust, no “trapped space” issues. | Requires cutting the line; transition welds between different schedules required. |

| Full Encirclement Wrap | High torque (moment) applications. | Distributes rotational forces excellently around the circumference. | Significant welding required; bulky. |

| Integral Forging | Critical, high-pressure, extreme cyclic service. | Highest integrity, best fatigue resistance, no attachment welds. | Very high cost, long lead times, custom engineering required. |

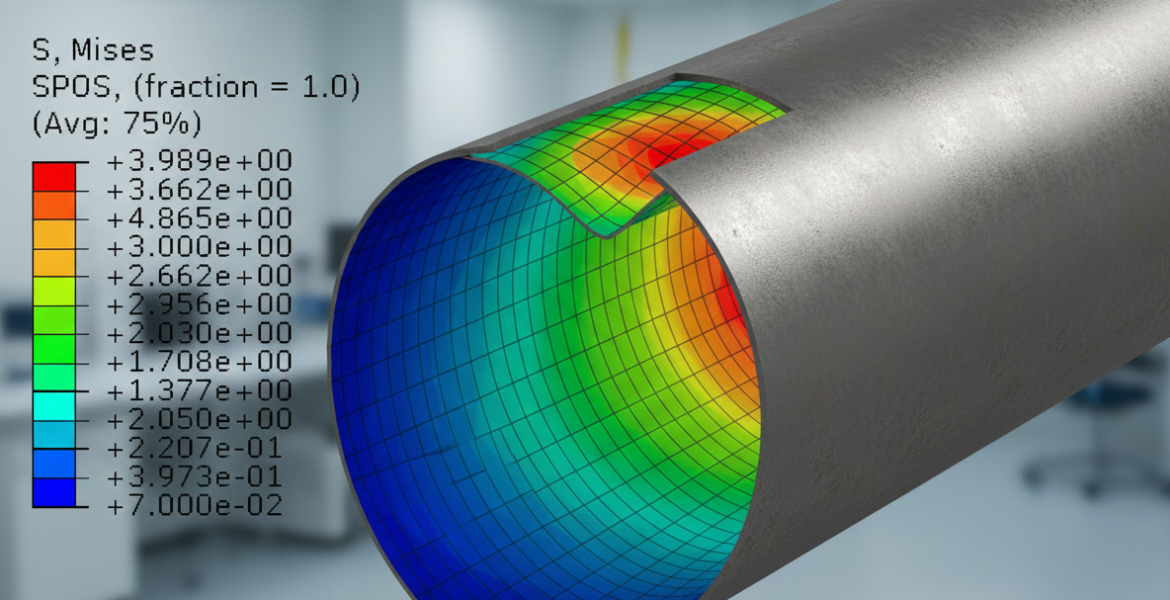

6. The Final Word: Finite Element Analysis (FEA)

For any significant moment anchor near critical equipment like a large pump, standard handbook calculations are often insufficient. The design of the attachment and the required pipe shell reinforcement should be verified using Finite Element Analysis (FEA). This computer modeling produces a “heat map” of stresses, proving that the chosen protection method truly reduces the stress in the pipe wall to allowable ASME B31 code limits.