Proving Integrity: Testing & Commissioning of Piping Systems 5/7

Piping Construction

Introduction: The Moment of Truth

Fabrication and installation may build the system, but testing and commissioning prove it. This is the stage where theory meets reality — where pressure gauges, pumps, and inspectors decide whether the system is ready to carry its load.

On a petrochemical project in Damietta, a hydrotest revealed a hidden crack in a weld that had passed visual inspection. The discovery delayed commissioning by three days but prevented a catastrophic failure. Testing is not a formality — it is the guardian of integrity.

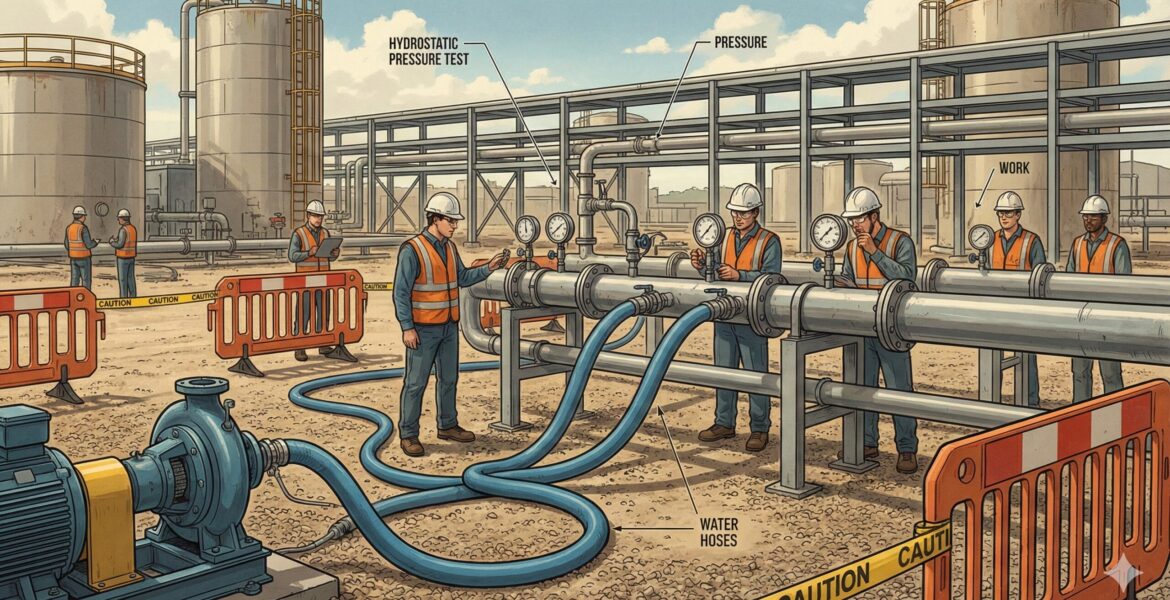

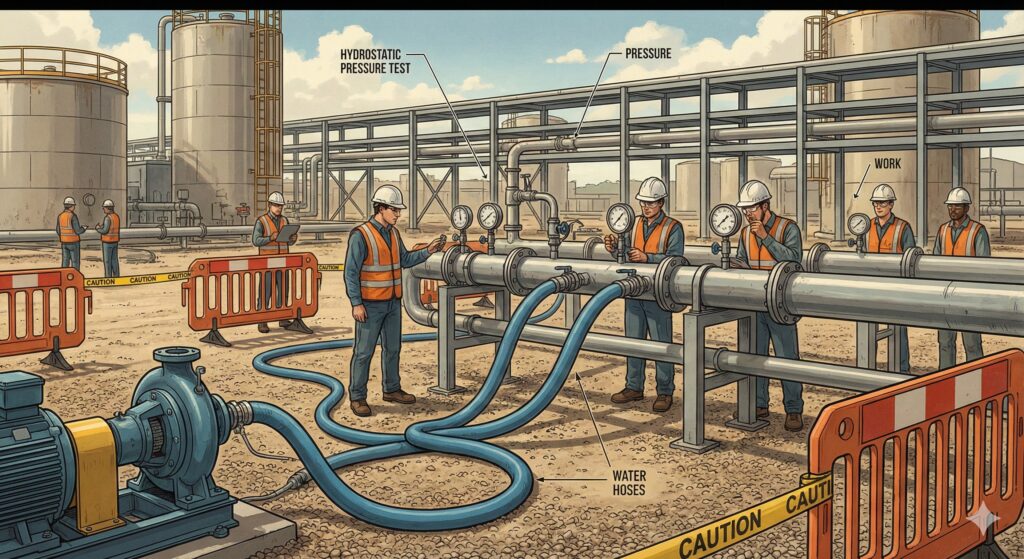

Hydrostatic Pressure Testing: Water as the Judge

Hydrotesting is the most common method to verify piping strength.

- Procedure: Fill the system with water, pressurize to 1.5 times design pressure, hold, and monitor.

- Standards: ASME B31.3 specifies test pressures, duration, and safety precautions.

- Safety: Exclusion zones, calibrated gauges, and slow pressurization are mandatory.

Real project lesson: On a refinery job, a gasket failed during hydrotest, spraying water across the site. The root cause was uneven bolt torque. Hydrotesting exposed the flaw before hazardous fluids ever entered the line.

Checklist:

- Use clean water to avoid contamination.

- Bleed air pockets before pressurization.

- Monitor pressure drop and inspect for leaks.

- Document results with calibrated instruments.

Pneumatic Testing: Air Under Pressure

When water is impractical, pneumatic testing steps in.

- Applications: systems where water could cause contamination, freezing, or damage.

- Risks: compressed air stores more energy than water — failures can be explosive.

- Precautions: barriers, remote monitoring, and gradual pressurization.

Case study: On a gas pipeline, pneumatic testing revealed micro leaks at threaded connections. Soap bubble testing pinpointed the defects, which were repaired before commissioning.

Best practices:

- Limit test pressure per ASME B31.3 guidelines.

- Use nitrogen or dry air for safety.

- Employ leak detection methods (bubble solution, ultrasonic sensors).

- Maintain strict exclusion zones.

Line Flushing & Cleaning: Clearing the Arteries

Before commissioning, lines must be clean. Debris, welding slag, and dust can damage pumps and valves.

- Methods: water flushing, air blowing, chemical cleaning.

- Standards: cleanliness criteria defined by project specifications and ISO guidelines.

- Documentation: flushing certificates confirm compliance.

Anecdote: On a desalination plant, debris left in a line damaged a high‑value pump impeller. The repair cost $70,000. Since then, flushing has been treated as sacred.

Flushing essentials:

- Use high‑velocity water or air to dislodge debris.

- Inspect strainers and filters during flushing.

- Record flow rates and duration.

- Verify cleanliness with visual and instrument checks.

Leak Testing & Reinstatement: The Final Seal of Approval

Leak testing ensures tightness before handover.

- Methods: helium leak detection, soap bubble tests, pressure decay monitoring.

- Standards: ASME and API define acceptable leak rates.

- Reinstatement: restoring valves, blinds, and instruments after testing.

Lesson learned: On a chemical plant, a valve was left blinded after testing. The oversight delayed commissioning by two days. A reinstatement checklist now prevents such errors.

Protocol:

- Perform leak tests at operating pressure.

- Document leak locations and corrective actions.

- Use reinstatement checklists signed by supervisors.

- Archive test certificates for client handover.

The Human Side of Testing

Testing days are tense. Inspectors watch gauges, welders hold their breath, managers pace. It’s the moment when months of work face judgment.

On one site, an inspector said, “Hydrotest day is like exam day. Everyone knows if we pass, we celebrate. If we fail, we learn.” That’s the spirit of commissioning — accountability and pride.

Conclusion: Testing as the Gatekeeper of Safety

Testing and commissioning are the gatekeepers of piping construction. They ensure that every weld, flange, and valve can withstand the pressures of operation.

It’s the final exam before the system earns its license to serve.

👉 Next Post: Quality Control & Safety