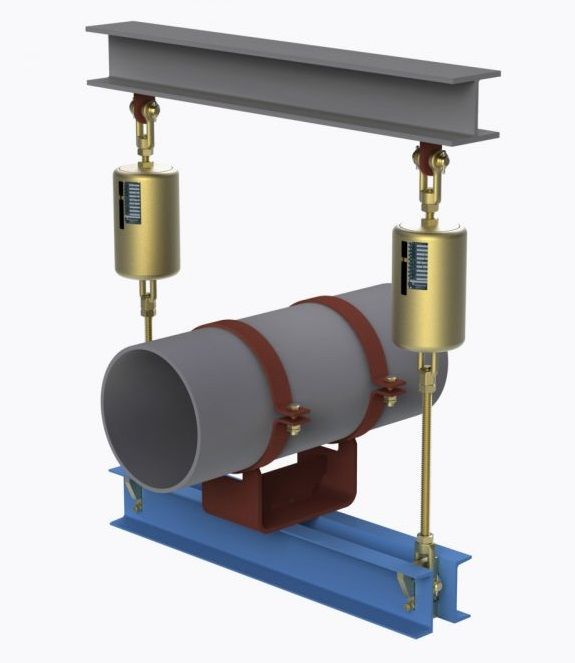

Post 5: The Clevis Hanger: The Workhorse of Suspension

Pipe Supports

1. Definition & Function Deep Dive

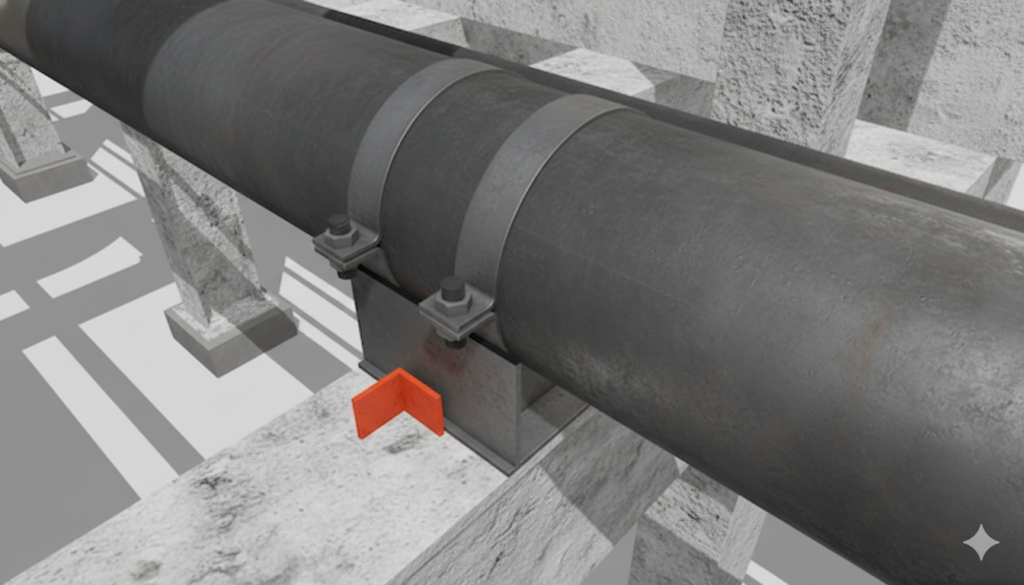

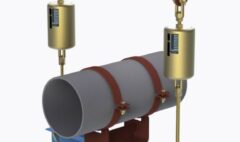

The clevis hanger is the standard solution for suspending cold, horizontal pipes from overhead structures where only limited adjustment is needed.9 It relies on gravity to keep the pipe nestled in the yoke.

2. Vendor & Industry Context

This is the bread-and-butter support for the fire protection (sprinkler), HVAC (chilled water), and plumbing industries. Vendors like Anvil and Cooper B-Line produce these in massive quantities, UL-listed for fire protection loads.

3. Design Limitations

Clevises are designed primarily for vertical gravity loads. They have very poor resistance to lateral (sideways) loads. If a pipe suspended by long clevis hangers is subjected to a sudden side-load (like water hammer or seismic activity), the hangers will swing like pendulums, putting massive bending stress on the threaded suspension rods at the ceiling connection point.

4. Maintenance & Failure Modes

- Rod Fatigue: If a system swings excessively over time, the threaded rod can fail due to metal fatigue right where it enters the ceiling anchor.

- Load Shift: On long runs of large diameter pipe, if one clevis slips down the threaded rod due to a loose nut, the load shifts to adjacent hangers, potentially overloading them in a cascading failure.