The Pipe Anchor: The Immovable Object

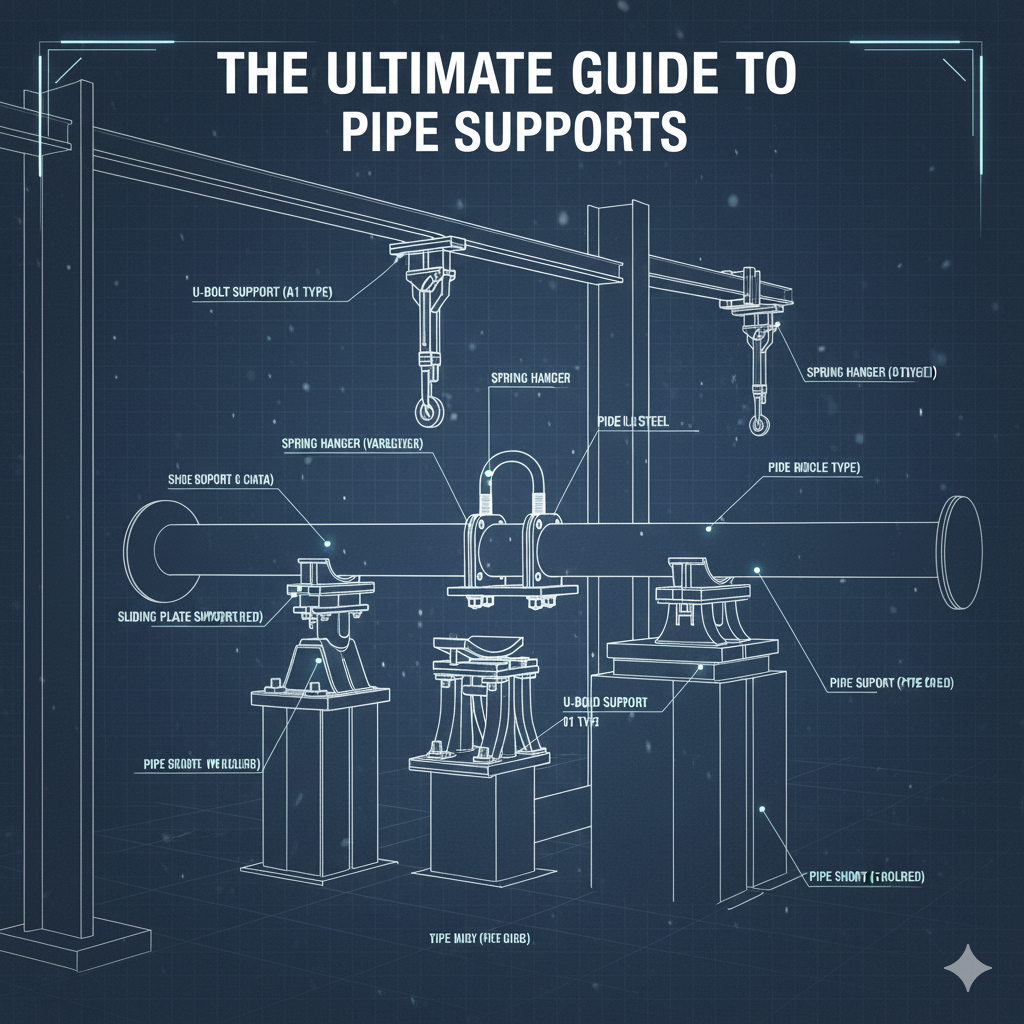

Pipe Supports

1. Definition & Function Deep Dive

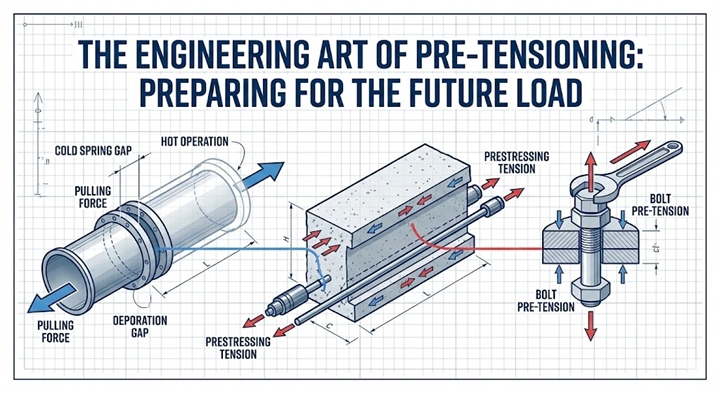

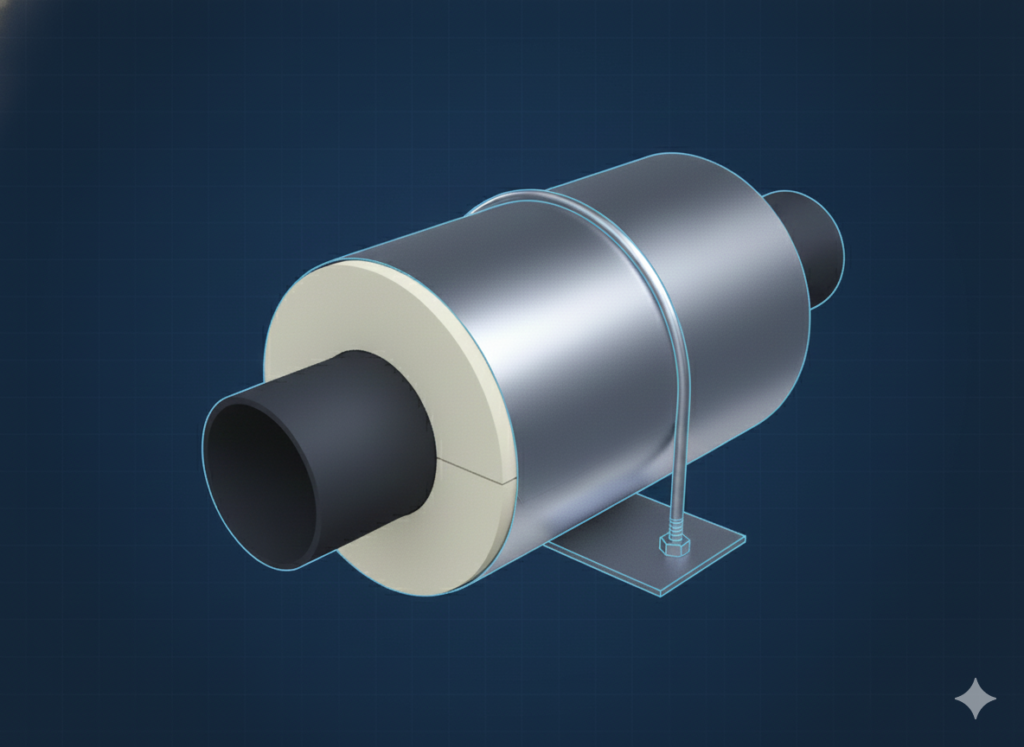

In the world of thermal expansion, the anchor is the “zero point.” The piping engineer uses anchors to divide a complex, sprawling piping network into smaller, manageable, independent sections. By fixing one point rigidly, they know exactly how much the pipe will grow in every other direction from that point, allowing them to design expansion loops or specify expansion joints.

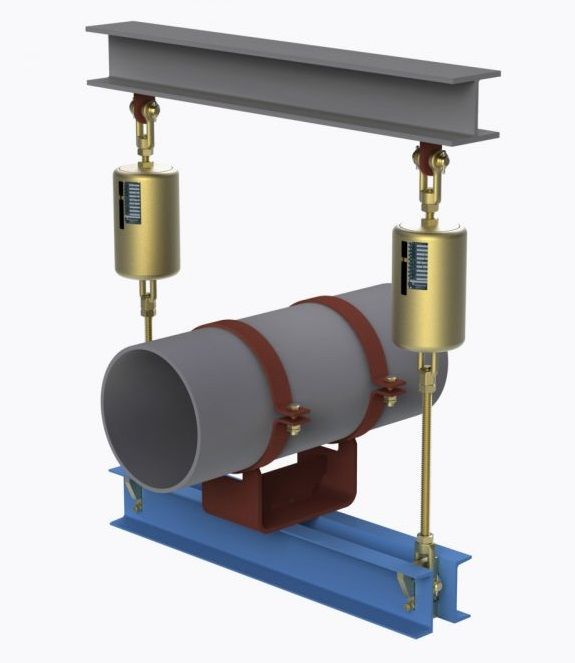

2. Engineering the Forces

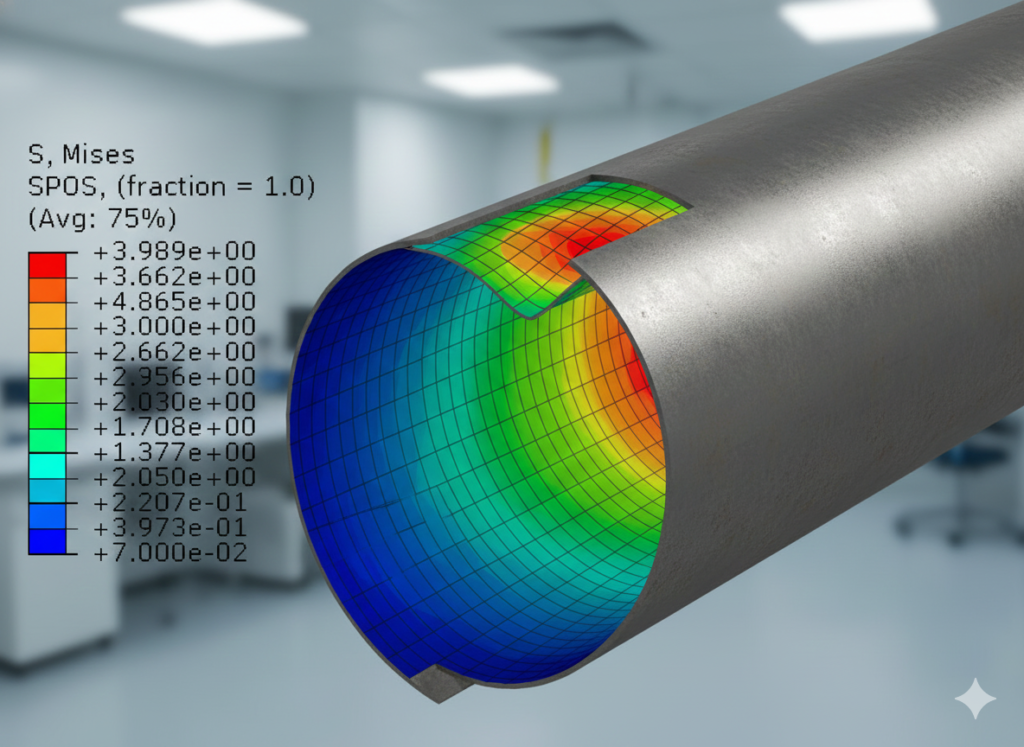

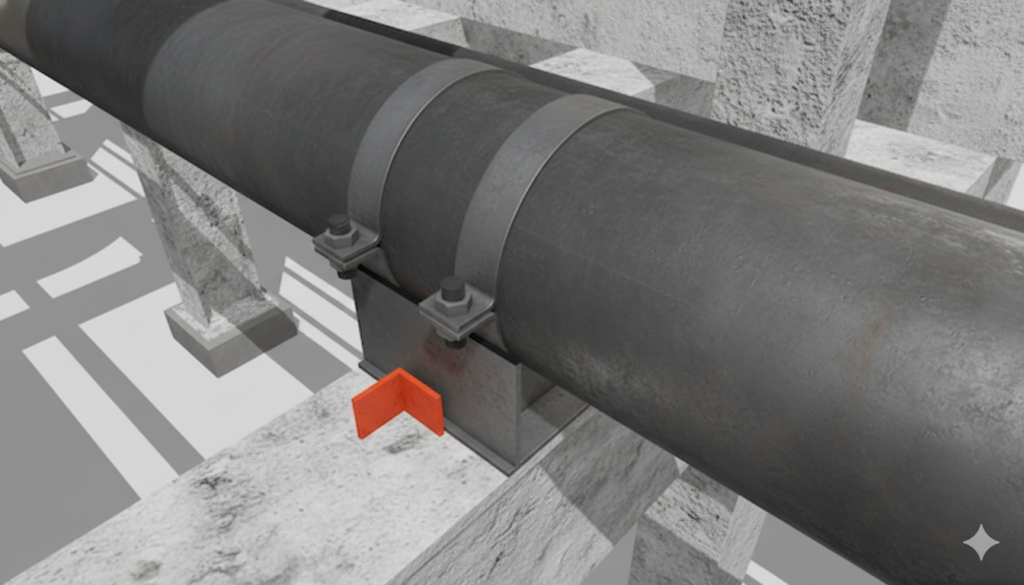

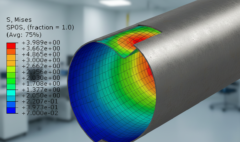

Anchors are not just heavy clamps. They must withstand immense forces—often tens of thousands of pounds of thrust created by thermal expansion trying to push the pipe through a wall, or the “kick” of a high-pressure safety relief valve opening. The structural engineer responsible for the steel beam or concrete pier must be given these exact loads by the piping engineer.

3. Moment anchor

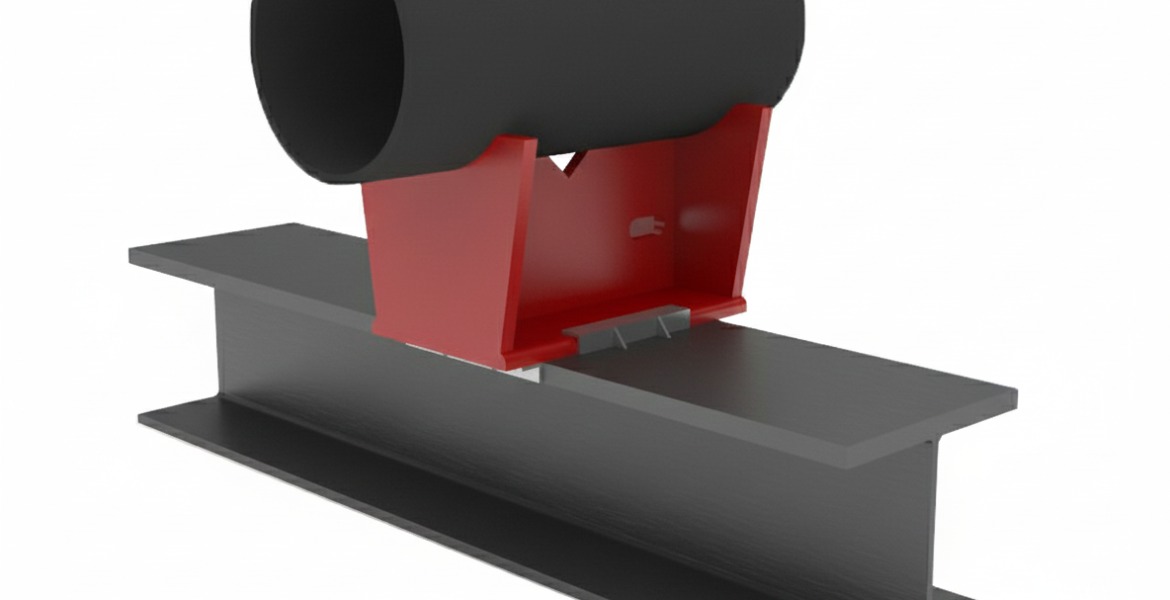

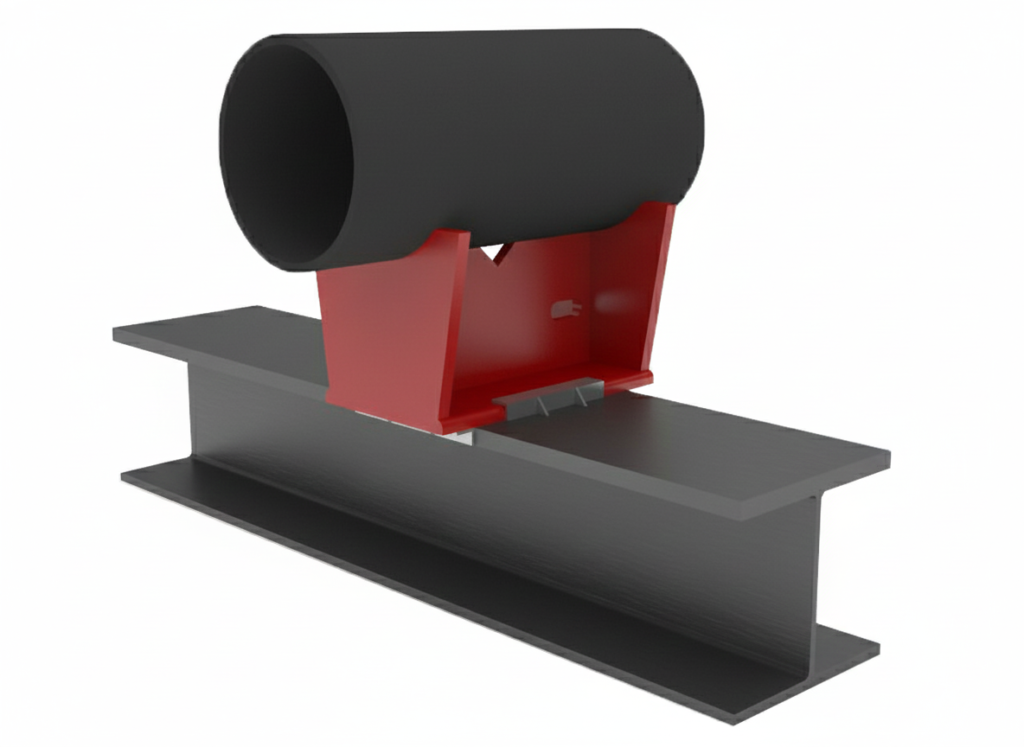

A moment anchor utilized in pump piping systems is a critical structural support designed specifically to protect sensitive rotating equipment from damaging rotational forces. Because pumps have very low allowable nozzle loads—often governed by stringent standards like API 610—they are highly susceptible to damage from piping stresses caused by thermal expansion, hydraulic pressure thrust, and operational vibration. If these forces manifest as torque (moments) acting on the pump flange, they can lead to severe casing distortion, shaft misalignment, premature bearing failure, and seal leakage. The moment anchor, typically strategically located near the pump on either the suction or discharge line, acts as a force-absorbing barrier; it rigidly constrains the pipe against rotation around its axis, effectively decoupling the piping system’s torque and transferring these immense loads safely into the supporting foundation or structural steel, rather than allowing them to be transmitted to the pump’s delicate nozzle connection.

4. Accident Scenarios

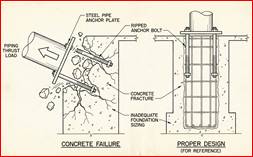

Failures here are often catastrophic.

- Concrete Failure: An anchor is only as strong as what it’s bolted to. There are many documented cases of anchor bolts ripping out of concrete piers because the concrete foundation wasn’t sized for the piping thrust load.

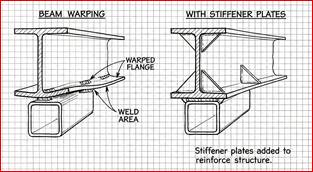

- Beam Warping: Welding a massive pipe anchor to the thin flange of a standard I-beam can warp the beam flange, compromising the main structure. Anchors often require localized stiffener plates added to the building steel.