The Piping Engineer’s Toolkit: Essential Software and Resources 💻

1 comment

The Piping Engineer’s Toolkit: Essential Software and Resources 💻

Introduction

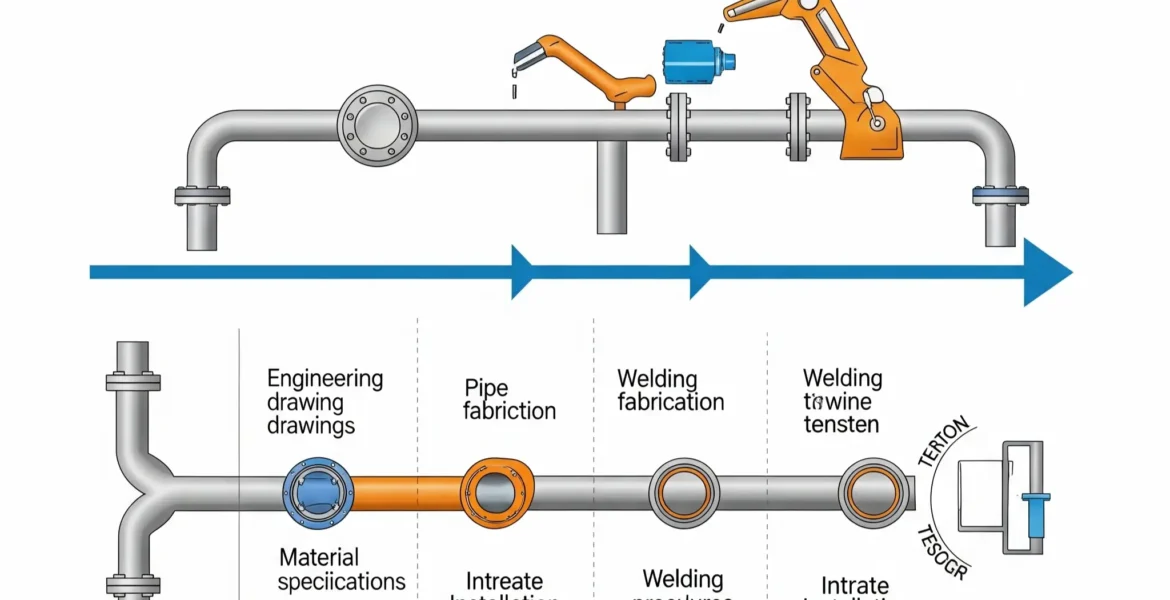

The evolution of piping engineering from drawing boards to sophisticated digital tools. How software enhances efficiency, accuracy, and collaboration.

Key Software Categories for Piping Engineers

2D CAD (Computer-Aided Design):

- AutoCAD: Still used for P&IDs, schematics, basic layouts, modifications.

- Importance: Foundational drafting skills.

3D Plant Design & Modeling Software:

- Examples: AVEVA PDMS/E3D, Intergraph SmartPlant 3D (S3D)/SmartPlant P&ID, AutoCAD Plant 3D, CADWorx.

- Capabilities: Intelligent P&IDs, 3D modeling of piping/equipment/structures, clash detection, automatic isometric and drawing generation, material take-off (MTO) generation, collaborative work environment.

- Benefits: Improved visualization, reduced errors, better coordination, lifecycle data management.

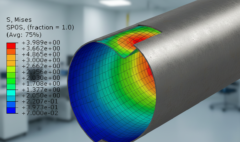

Pipe Stress Analysis Software:

Specialized Calculation & Analysis Tools:

- Fluid flow simulators (for pressure drop, line sizing).

- Flange management software.

- Weld management software.

- Nozzle flexibility analysis (e.g., FEA tools, WRC 107/297/537 based calculators).

Material Selection Databases & Software:

- Software that helps select materials based on process conditions, corrosion data.

- Access to ASTM, ASME material property data.

Essential Standards and Resources:

- ASME Codes: B31 suite (B31.3 paramount for process piping), Section II (Materials), Section V (NDE), Section VIII (Pressure Vessels), Section IX (Welding).

- API Standards: API 570 (Piping Inspection), API 600/602 (Valves), API 610 (Pumps), API 520/521 (Pressure Relief Systems).

- ASTM Standards: For material specifications (e.g., A106, A312).

- Industry Handbooks: Crane TP-410 (Flow of Fluids), Nayyar Piping Handbook.

- Manufacturer Catalogs: For valves, fittings, specialty items.

Importance of Continuous Learning for New Tools & Standards:

- Software updates frequently, new tools emerge.

- Codes and standards are periodically revised.

- Need for staying current to remain competitive and ensure compliance.

Conclusion & Call to Action:

The modern piping engineer relies heavily on a suite of powerful software and a deep understanding of codes and standards. Targeted training courses for specific piping software (e.g., CAESAR II, S3D, Plant 3D) and workshops on ASME code application are invaluable for developing proficiency and leveraging these tools effectively to produce safe, efficient, and compliant designs.

Related Posts

Pipe Shell at Moment Support

January 8, 2026

The Constant Spring Hanger: Engineering Magic

January 7, 2026

The Variable Spring Base Support (Spring Can)

January 6, 2026

The Variable Spring Hanger: The Standard Solution

January 5, 2026

Comment (1)

Osama

👍