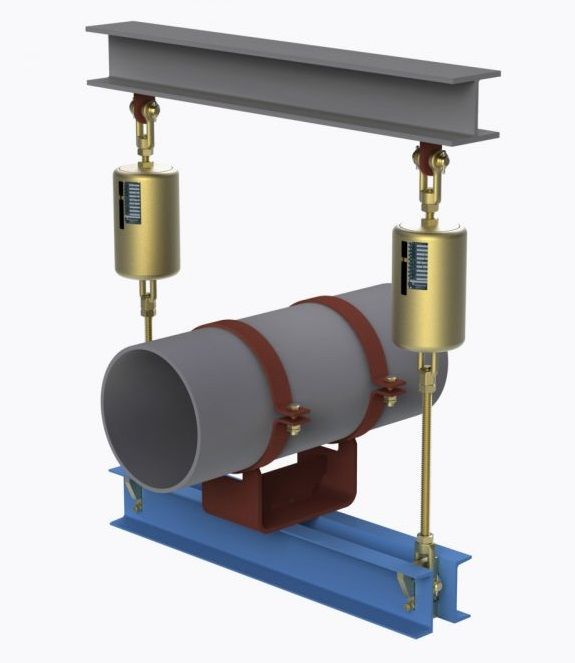

The Variable Spring Hanger: The Standard Solution

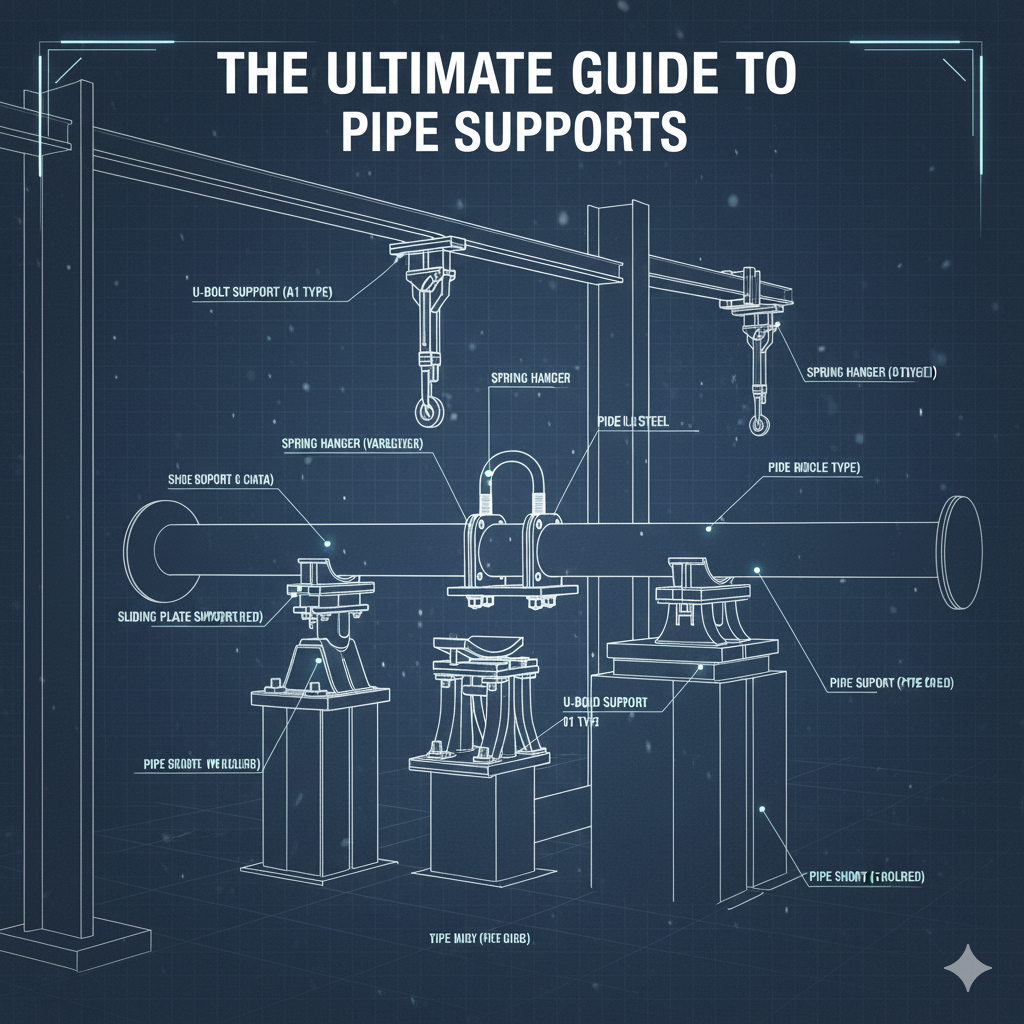

Pipe Supports

1. Definition & Function Deep Dive

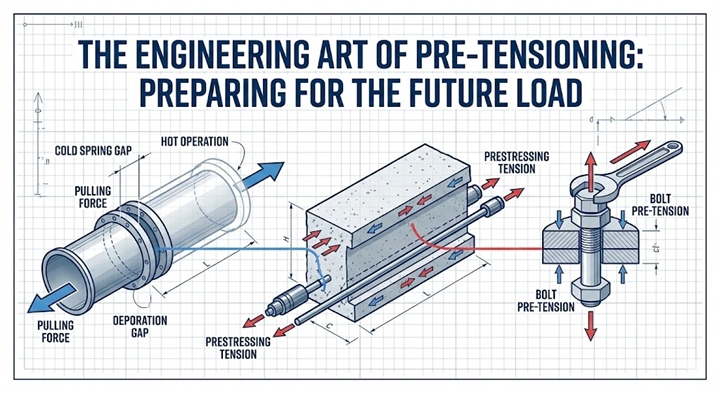

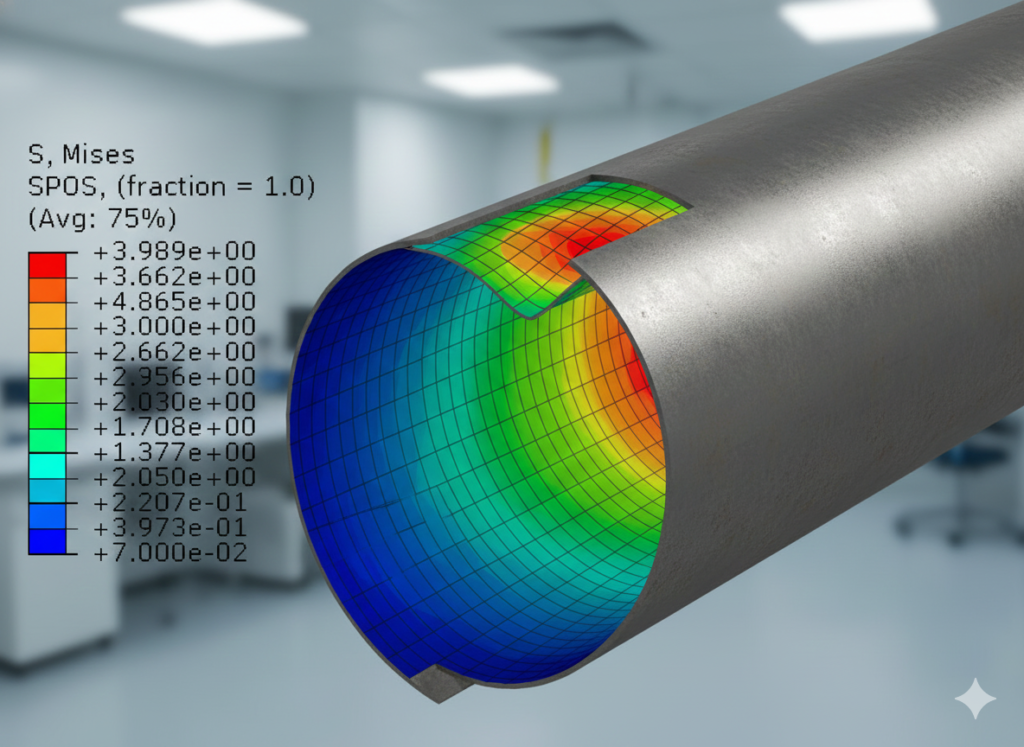

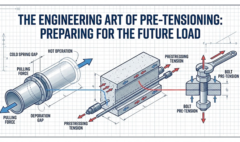

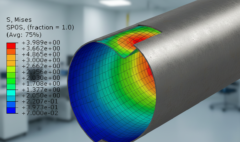

As a pipe moves up or down due to temperature changes, the spring inside the hanger compresses or decompresses. According to Hooke’s Law (F=kx), as the spring changes length, the force it exerts changes. A variable spring therefore exerts a different supporting force on the pipe in the hot condition versus the cold condition.

2. Vendor Selection Criteria (Variability)

Vendors like ASC (Anvil), Lisega, and Carpenter & Paterson rate their cans by “variability.” The goal of the piping designer is to keep the load variation on connected equipment low.

- Industry Rule of Thumb: Variable springs are generally used only if the variation between cold load and hot load is less than 25%. If the load changes more than that, the stress on connected equipment is usually too high, and a Constant Spring is needed.

The #1 Troubleshooting Issue: Travel Stops

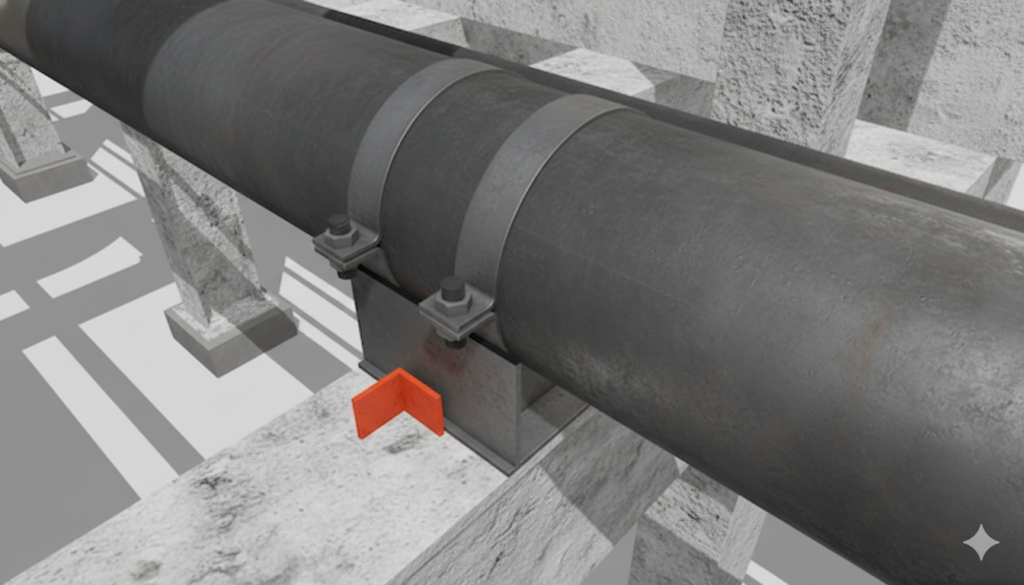

Variable springs are shipped from the factory with “travel stops” (usually metal plates or pins) inserted. These lock the spring at the calculated “cold load” position, making it act like a rigid rod during installation and hydro-testing.

- The Failure Mode: It is distressingly common for construction crews to forget to remove these stops before the plant starts up. When the pipe heats up and tries to move down, it’s held rigidly by the locked spring. This transfers massive loads onto pump nozzles, frequently causing damage during the first operational run. Always verify travel stops are removed before startup.

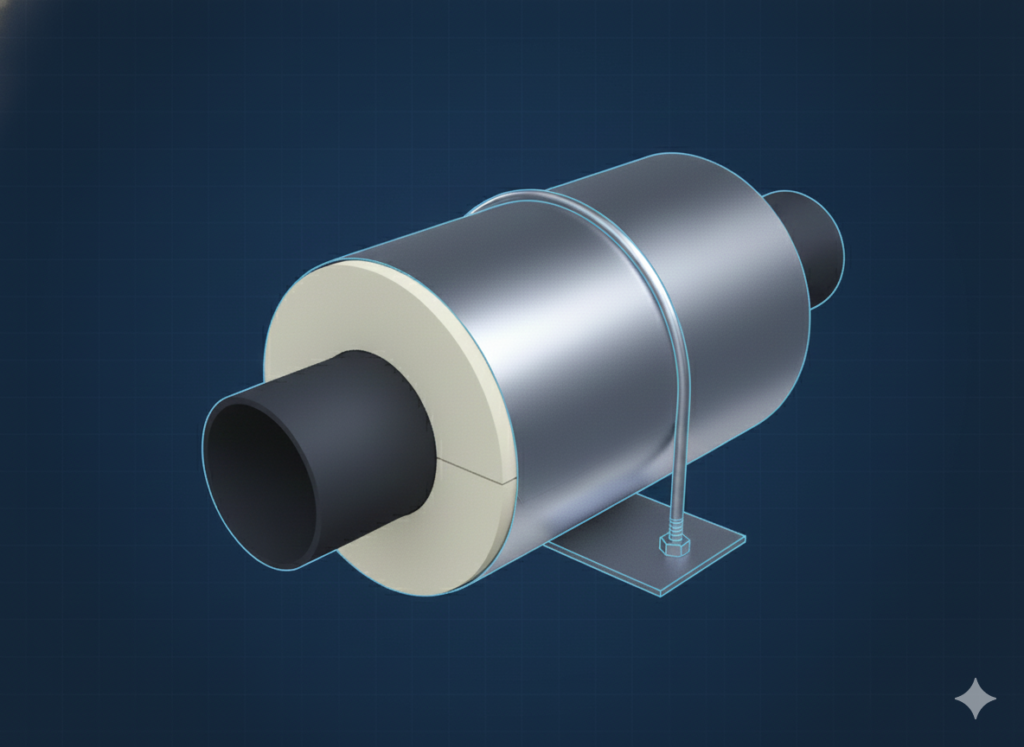

3. The Impact of Low-Temperature Weather on the Spring Mechanism

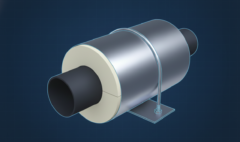

While the high-strength steel alloys used for spring coils are generally resilient to standard atmospheric temperature changes, extreme low-temperature environments (such as arctic conditions or severe winter freezes) pose significant operational risks. The primary danger is not necessarily the metallurgy of the spring itself becoming brittle, but rather the ingress of moisture. Rain, melting snow, or condensation can accumulate inside the spring housing (the “can”). If the ambient temperature drops below freezing, this trapped water turns into ice, effectively cementing the spring coils together or freezing the load flange guide mechanism. A frozen spring hanger ceases to function as a variable support and becomes a rigid strut. When the plant starts up and the pipe begins thermal expansion, the frozen spring will not compress, transferring immense, uncalculated loads back onto the piping system and critical equipment nozzles, potentially leading to catastrophic failure. For freezing environments, manufacturers must provide weather-sealed housings or ensure adequate drainage holes to prevent water accumulation.

4. How the Environment Impacts Paint System Selection

The selection of the coating system for a spring hanger is not merely an aesthetic choice; it is a critical life-cycle engineering decision dictated by the operating environment. Spring hangers are uniquely vulnerable to corrosion due to their complex geometry—the tight spaces between spring coils and the internal mechanisms inside the housing create ideal crevice corrosion sites that are difficult to inspect and maintain. In a standard indoor utility setting, a basic shop primer and finish coat may suffice. However, in coastal or offshore marine environments subject to salt spray, standard paint will fail rapidly, leading to rusted coils that snap under load or mechanisms that seize up. These aggressive environments require robust solutions such as hot-dip galvanizing of the entire assembly or multi-coat systems utilizing zinc-rich primers and high-build epoxy intermediates. Similarly, in chemical plants where corrosive fumes are present, the paint system must be chemically resistant to the specific atmospheric contaminants to prevent rapid degradation of the support structure.