Welding and NDE for Piping: Ensuring Joint Integrity and Compliance (ASME IX, V, B31.3) 🔥🔬

Welding and NDE for Piping: Ensuring Joint Integrity and Compliance (ASME IX, V, B31.3) 🔥🔬

Introduction:

The critical role of welding in creating permanent, leak-tight joints in metallic piping systems. The equal importance of Non-Destructive Examination (NDE) in verifying weld quality.

Why Welding is the Preferred :

Joining Method for Critical Piping: Strength, integrity, ability to withstand high pressures and temperatures.

Common Welding Processes Used in Piping Fabrication (with brief descriptions):

- Shielded Metal Arc Welding (SMAW) / “Stick Welding”: Versatile, widely used, especially for field welds.

- Gas Tungsten Arc Welding (GTAW) / TIG Welding: High-quality welds, good for root passes and alloy materials. Slower process.

- Gas Metal Arc Welding (GMAW) / MIG Welding: Faster than TIG, good for shop fabrication. Can be semi-automatic or automatic.

- Flux-Cored Arc Welding (FCAW): Similar to MIG but with flux inside the wire. Good for outdoor/field conditions.

- Submerged Arc Welding (SAW): High deposition rate, automated process, used for longitudinal and circumferential welds in shop environments, typically for larger diameter pipes.

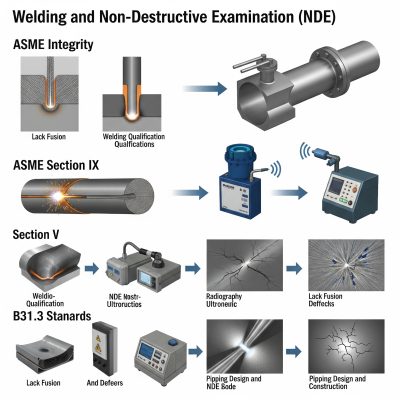

Fundamentals of Welding Procedure and Welder Qualification (ASME Section IX):

- Welding Procedure Specification (WPS): The “recipe” for making a sound weld. Details essential variables (process, materials, preheat, PWHT, technique, etc.).

- Procedure Qualification Record (PQR): The documented record of the actual welding and testing done to qualify a WPS. Includes destructive test results.

- Welder Performance Qualification (WPQ): Documentation that a specific welder has demonstrated the ability to make sound welds according to a qualified WPS.

- ASME Boiler and Pressure Vessel Code, Section IX (Welding, Brazing, and Fusing Qualifications): The primary code governing WPS and welder/operator qualification. Its principles are referenced by ASME B31.3 (Chapter V).

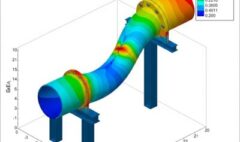

Preheat and Post-Weld Heat Treatment (PWHT):

- Preheat: Heating the base metal before welding to slow cooling rate, reduce shrinkage stresses, minimize cracking risk (especially for alloy steels, thick sections). Requirements in ASME B31.3 Table 330.1.1.

- PWHT: Heating the completed weldment to a specific temperature for a period to relieve residual stresses, temper the microstructure, improve toughness. Requirements in ASME B31.3 Table 331.1.1.

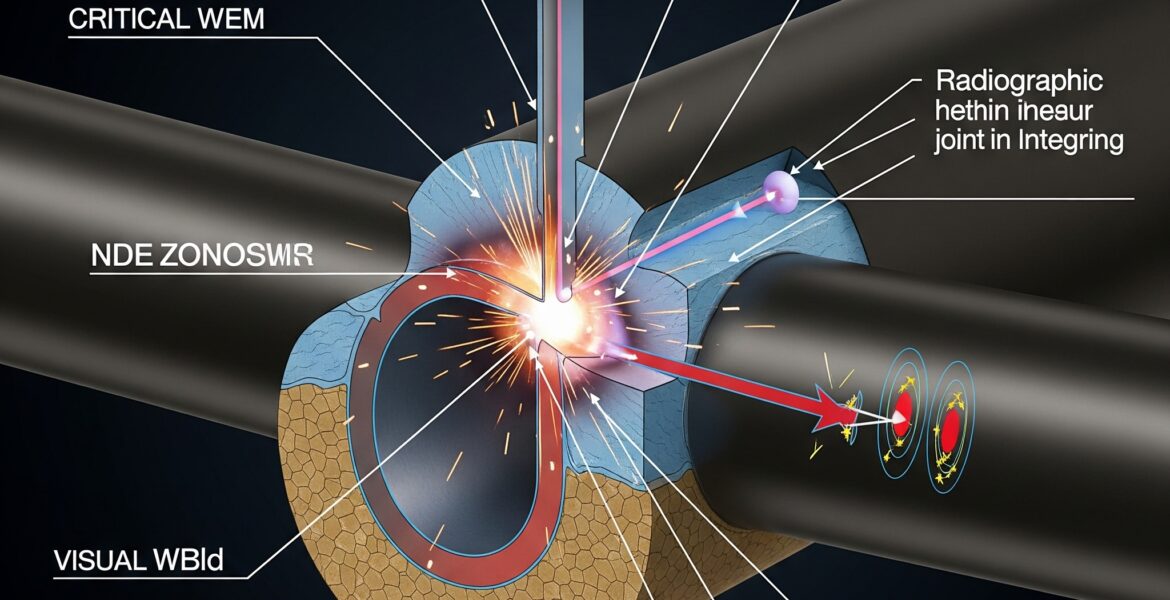

Non-Destructive Examination (NDE) of Welds:

- Purpose: To detect surface and subsurface flaws without destroying the component.

- ASME Boiler and Pressure Vessel Code, Section V (Nondestructive Examination): Provides methodologies and acceptance criteria (though B31.3 often provides its own specific acceptance criteria).

Common NDE Methods Used for Piping Welds (ASME B31.3 Chapter VI, Table 341.3.2 specifies extent):

- Visual Examination (VT): Most common, checks for surface defects, profile, size.

- Liquid Penetrant Testing (PT): Detects surface-breaking flaws (cracks, porosity).

- Magnetic Particle Testing (MT): Detects surface and near-surface flaws in ferromagnetic materials.

- Radiographic Testing (RT): Uses X-rays or gamma rays to detect internal flaws (porosity, slag, cracks, lack of fusion).

- Ultrasonic Testing (UT): Uses sound waves to detect internal flaws. Can also measure thickness. Phased Array UT (PAUT) and Time-of-Flight Diffraction (TOFD) are advanced UT techniques.

- Acceptance Criteria: Defined in ASME B31.3, Para. 341.3.2 and other paragraphs in Chapter VI, based on the fluid service category.

Weld Traceability and Documentation:

Maintaining records of welders, WPSs used, NDE results for each weld. Critical for quality assurance.

Common Weld Defects and Their Causes:

Porosity, slag inclusions, lack of fusion, incomplete penetration, cracks, undercut, overlap.

Conclusion & Call to Action:

Sound welds are the backbone of piping system integrity. A thorough understanding of welding processes, qualification requirements under ASME Section IX, and NDE methods as per ASME Section V and B31.3 Chapter VI is essential for engineers, inspectors, and welders. Training programs on welding technology, NDE methods, and ASME code interpretation (Sections V, IX, and B31.3) are vital for ensuring that piping joints are fabricated to the highest standards of quality and safety.