Solar Energy Fundamentals

Renewable Energy

Introduction

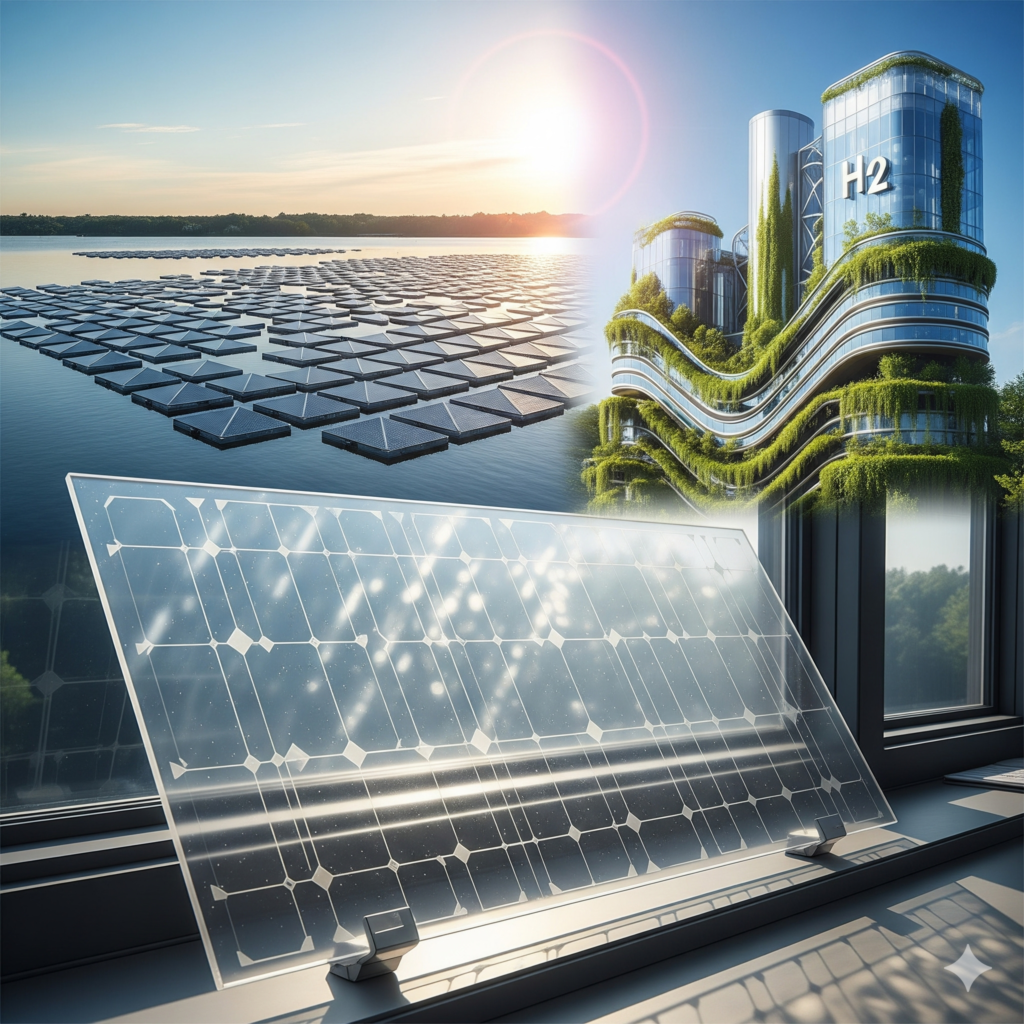

Solar energy has evolved from a niche space-exploration technology to the cheapest source of electricity in history. But for engineers and project managers, understanding “solar” goes beyond simply installing panels. It requires a grasp of Photovoltaic (PV) physics, irradiance data, and the balance of system (BoS) components. In this post, we unpack the technical fundamentals of Solar PV.

Purpose: Harvesting the Sun

Solar PV converts sunlight directly into electricity using the photovoltaic effect. The goal is simple: maximize the conversion of solar irradiance (W/m²) into usable electrical power (kWh), while minimizing losses due to heat, resistance, and shading.

Inputs: The Physics of Efficiency

- Irradiance: The power of solar radiation per unit area. Standard Test Conditions (STC) assume 1000 W/m², but real-world engineering must account for local DNI (Direct Normal Irradiance) and GHI (Global Horizontal Irradiance).

- The Semiconductor: Most panels use silicon. When photons hit the silicon cell, they knock electrons loose, creating a current.

- Temperature Coefficient: Ironically, solar panels hate heat. As temperature rises, voltage drops, reducing efficiency. High-quality panels have a lower temperature coefficient (e.g., -0.3%/°C).

Process Steps: Designing a Solar Solution

- Site Assessment: Using tools like PVSyst or Helioscope to model shading and sun path.

- Component Selection: Choosing between Monocrystalline (higher efficiency, higher cost) vs. Polycrystalline (lower cost, larger footprint).

- Inverter Configuration: Matching string voltage to the inverter’s MPPT (Maximum Power Point Tracking) window to ensure optimal energy harvest.

- Racking & Mounting: Engineering the structural load to withstand wind uplift and snow loads.

Emerging Technologies

- Bifacial Panels: These capture reflected light (albedo) from the ground on the rear side of the panel, boosting output by 5-30%.

- Perovskites: A new class of materials that promises higher efficiency layers that can be printed or painted, potentially disrupting the silicon market.

Common Pitfalls

- Ignoring Soiling: Dust and bird droppings can cause “hot spots” that damage cells and reduce string output.

- Undersizing Inverters: While some “clipping” (overloading the inverter) is acceptable to maximize early morning/late afternoon production, excessive DC/AC ratios reduce equipment life.

Example: The Utility-Scale Shift

Consider a 100MW solar farm in a desert region. By switching from fixed-tilt racking to Single-Axis Trackers (which follow the sun east-to-west), the project increased its energy yield by 25%, significantly lowering the Levelized Cost of Energy (LCOE) despite the higher mechanical CAPEX.